Chapter 9

The Future of Smart Supply Chains

"In the next decade, AI, blockchain, and 5G will redefine supply chains, creating seamless, automated, and resilient networks. Those who fail to adapt will be left behind." — Jeff Bezos, Founder of Amazon

Chapter 9, The Future of Smart Supply Chains, explores the technologies and trends that will drive the next wave of innovation in supply chain management. It discusses the transformative impact of AI, blockchain, and 5G in creating smarter, faster, and more secure supply chains. The chapter also examines the move toward fully autonomous operations and the potential of quantum computing to solve complex supply chain optimization problems. Sustainability and corporate social responsibility (CSR) are highlighted as key priorities, with an emphasis on how future supply chains will integrate these values through emerging technologies such as digital twins, edge computing, and augmented reality.

9.1. The Next Generation of Smart Supply Chains

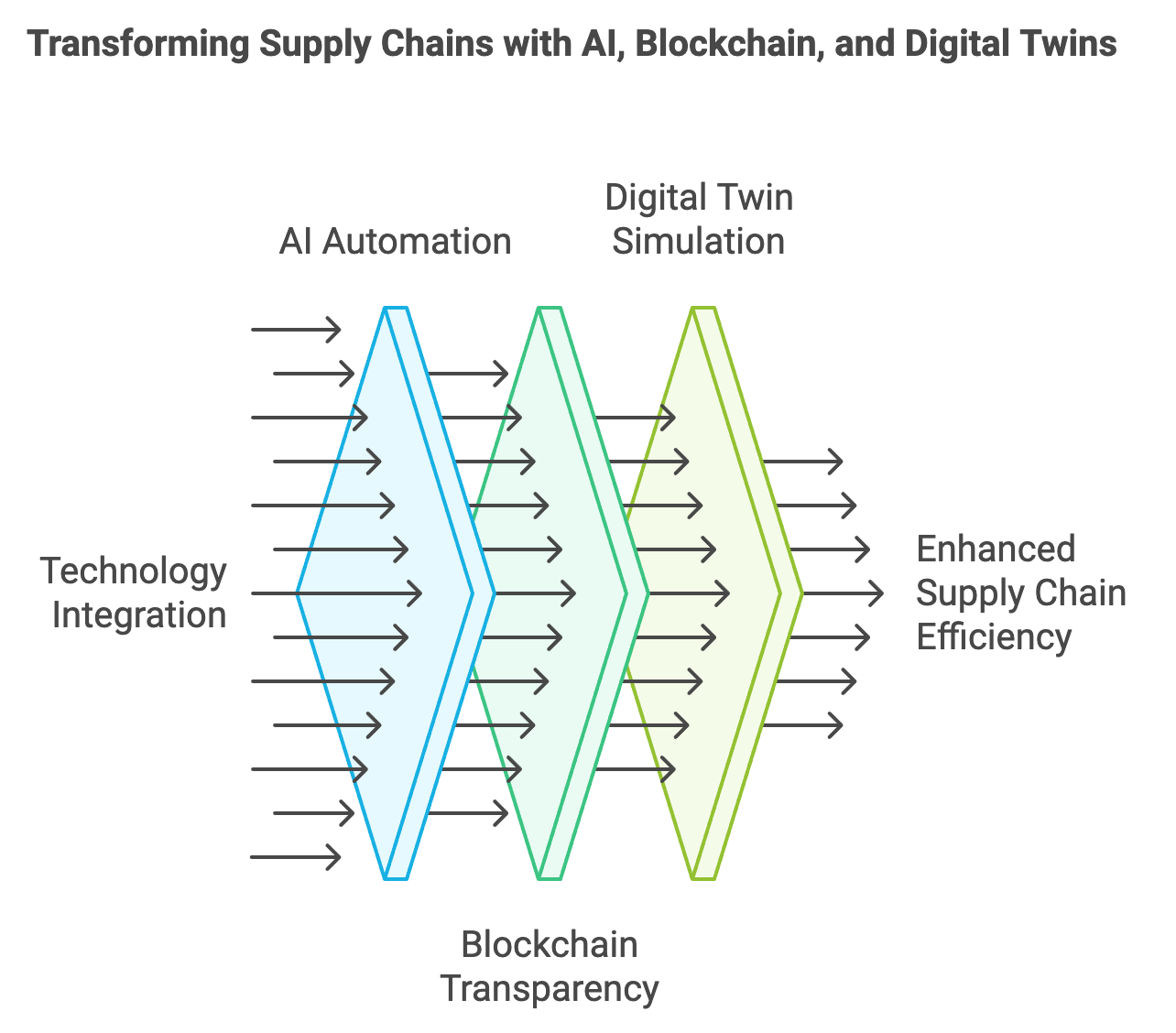

The integration of Artificial Intelligence (AI), Blockchain, and Digital Twin technologies marks a pivotal shift in supply chain management, driving unprecedented levels of automation, transparency, and real-time responsiveness (Caro et al., 2022; KPMG, 2023). While each technology brings distinct benefits, their convergence yields synergistic outcomes that empower organizations to tackle global uncertainties, complex logistics scenarios, and shifting consumer demands with agility (PwC, 2024). AI delivers predictive analytics, Blockchain assures data integrity, and Digital Twins offer dynamic simulations—together forming a cohesive ecosystem that redefines supply chain operations.

Figure 1: Key technologies to transform supply chains.

AI stands at the forefront of the new supply chain paradigm, enabling predictive analytics, process automation, and data-driven decision-making (Zhang, Chen, and Li, 2021). Machine learning algorithms evaluate massive data streams—such as historical demand patterns, real-time inventory levels, and transportation routes—to forecast market fluctuations, minimize bottlenecks, and optimize resource allocation (Deloitte, 2023). This enhanced precision helps reduce operational waste, streamline production scheduling, and align delivery schedules with actual demand (Lu et al., 2022). As consumer preferences evolve more rapidly, AI’s predictive capabilities facilitate timely, evidence-based adjustments that mitigate risks such as overstock or late delivery.

Major logistics players exemplify AI’s transformative power. UPS, for instance, relies on AI-driven route optimization to adapt to real-time variables like weather or traffic conditions, reducing fuel consumption and improving delivery windows (PwC, 2024). Similarly, DHL deploys AI across its global operations to automate warehousing tasks and predict demand surges, thus maintaining flexibility and consistent service quality (KPMG, 2023). By harnessing AI, these companies enhance productivity and boost customer satisfaction—an increasingly vital goal in an era of same-day and next-day shipping standards (Zhang, Chen, and Li, 2021).

Blockchain technology addresses a core challenge in sprawling, multi-tiered supply chains: the need for secure, verifiable data exchange among diverse stakeholders (Demestichas and Daskalakis, 2020). By establishing an immutable, decentralized ledger, Blockchain ensures that every transaction or exchange is recorded and accessible to authorized participants, eliminating discrepancies and reducing fraud. Smart contracts add another layer of efficiency by automating processes once specific conditions are met—streamlining tasks like verifying product provenance or initiating payments (KPMG, 2023).

Industries requiring rigorous compliance and traceability, such as pharmaceuticals and food safety, have led the way in blockchain adoption (EY, 2025). Companies like DHL leverage blockchain to verify that products are stored and transported under appropriate conditions, drastically curbing counterfeit risks and reinforcing consumer confidence (PwC, 2024). Additionally, cross-industry consortia can use blockchain for compliance checks—ensuring raw materials meet ethical and environmental standards, all while minimizing the burdensome costs of conventional audits (Demestichas and Daskalakis, 2020).

Digital Twin technology furnishes a dynamic, virtual representation of physical supply chain assets and processes, updating continuously via IoT sensors (Wang, Zhang, and Song, 2022). This functionality permits constant monitoring and scenario testing without interrupting live operations. By simulating conditions—such as a sudden spike in demand or a transportation delay—digital twins help companies explore corrective strategies and anticipate how changes might ripple through their logistics network (Deloitte, 2023).

Global logistics providers demonstrate the potential of digital twins in optimizing fleet usage and predictive maintenance (Lu et al., 2022). DHL, for instance, uses virtual replicas of its delivery fleets and distribution centers to forecast vehicle health, regulate fuel consumption, and schedule proactive maintenance. In emerging markets, digital twins provide critical visibility over supply chain bottlenecks—empowering companies to allocate resources effectively even amidst infrastructure challenges or regulatory uncertainties (EY, 2025).

Collectively, AI, Blockchain, and Digital Twin technologies generate synergies that surpass the impact of each individual innovation (Caro et al., 2022). AI’s predictive insights can feed into digital twins, refining simulations with real-time data, while blockchain ensures that all stored and transmitted information retains integrity and security (Demestichas and Daskalakis, 2020). The result is a holistic supply chain ecosystem that adapts rapidly, identifies vulnerabilities, and automates critical workflows from sourcing to last-mile delivery (KPMG, 2023).

For emerging markets, these convergent technologies offer a pathway to global competitiveness by leveling the playing field. Blockchain-based mechanisms can establish compliance and quality assurance at reduced cost, while digital twins guide infrastructure and resource planning (Wang, Zhang, and Song, 2022). Simultaneously, AI assists in anticipating local market demand and optimizing limited logistics capacity, thus empowering firms in developing regions to integrate seamlessly into global supply networks (EY, 2025).

Real-world applications highlight how these technologies reinforce one another. In the automotive sector, AI-driven predictive models anticipate component shortages, digital twins test out supply chain adjustments, and blockchain verifies parts’ authenticity and compliance (PwC, 2024). Similarly, the fashion industry employs these tools to combat counterfeit goods, forecast seasonal demand, and optimize e-commerce fulfillment. Ongoing research from both industry and academia underscores that wider adoption of these synergistic solutions will continue to enhance visibility, sustainability, and agility across multiple sectors (Zhang, Chen, and Li, 2021).

Looking forward, as global supply chains encounter ever more complex risks—from climate-related disruptions to shifting geopolitical landscapes—these combined innovations will likely transition from competitive advantage to essential infrastructure (Deloitte, 2023). Firms that invest in integrated AI, Blockchain, and Digital Twin systems stand poised to excel in an era defined by rapid change and high consumer expectations. By securing data integrity, delivering real-time insights, and enabling proactive crisis management, next-generation smart supply chains promise robust and sustainable operations across the world’s diverse markets (KPMG, 2023).

9.2. Autonomous Supply Chains

Autonomous supply chains represent a groundbreaking evolution in supply chain management, characterized by minimal human oversight and extensive integration of AI, robotics, and IoT-based data exchange (Deloitte, 2023). In such systems, machines and algorithms dynamically coordinate tasks—ranging from warehouse operations and inventory control to transportation and last-mile delivery—using real-time analytics and predictive models to achieve remarkable levels of efficiency and agility (KPMG, 2023). By shifting decision-making from human-centric processes to AI-driven logic, autonomous supply chains can adapt more rapidly to disruptions, optimize resource allocation, and bolster throughput with fewer errors (PwC, 2024). The practical upshot is a self-regulating ecosystem that continuously tunes itself for optimal performance, reducing costs and enhancing customer satisfaction.

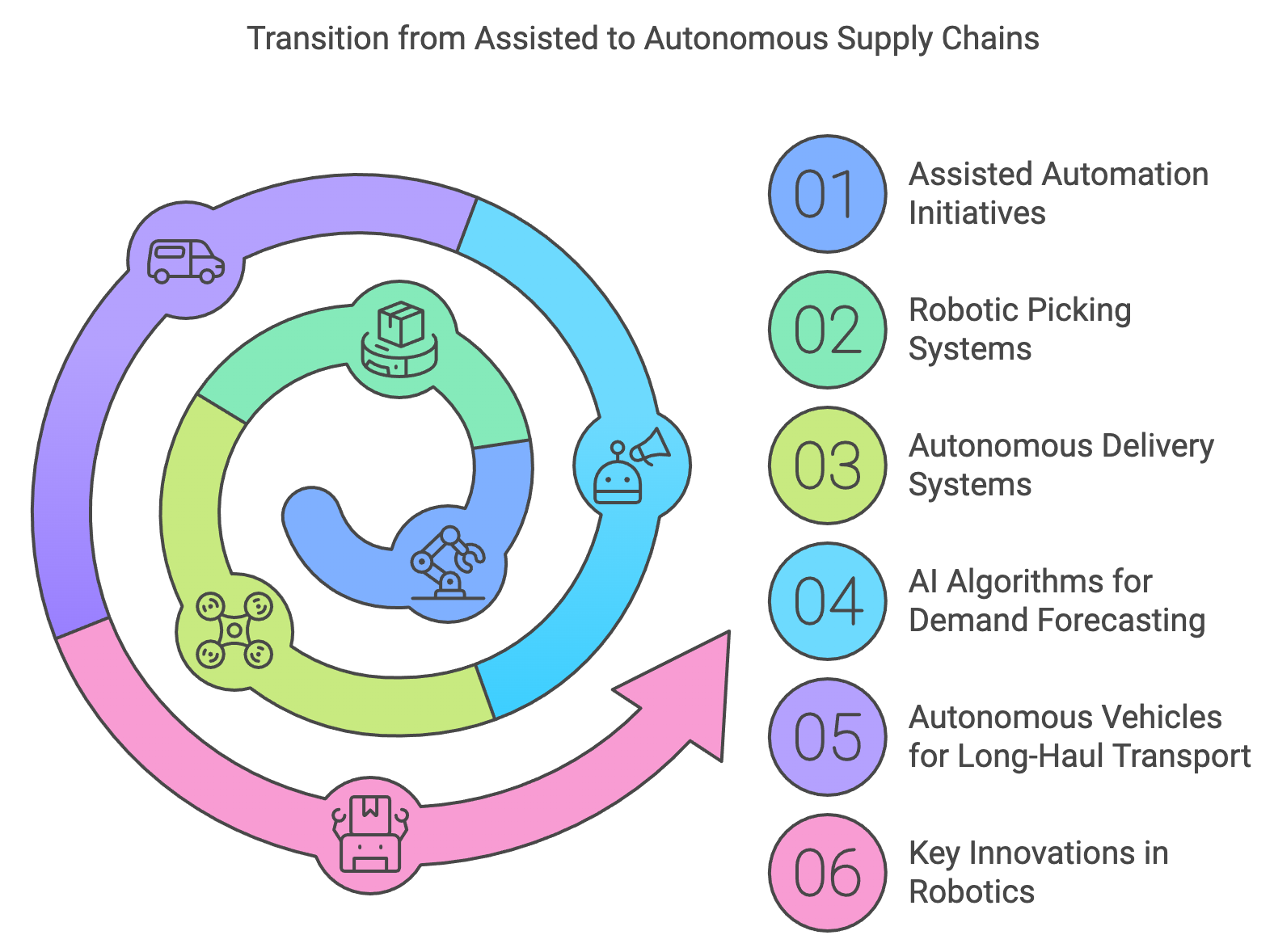

Figure 2: Journey from assisted to autonomous supply chains.

Most supply chains today still operate under an assisted automation model, wherein human workers collaborate with robotics or semi-automated systems. Typical examples include robotic picking solutions that help retrieve goods more efficiently or driver-assist technologies that enhance safety on the road. Although these innovations improve precision and reduce physical strain, humans retain responsibility for critical decisions and supervisory tasks (Köhn, 2021).

However, the ambition of fully autonomous supply chains goes further, allowing AI algorithms and advanced robotics to control end-to-end processes. For instance, inventory management systems powered by machine learning can predict stock requirements in real time, while autonomous vehicles—both on roads and in skies—transport products without human intervention (Mani, Delgado, and Hazen, 2021). Research indicates that such transitions can cut operational costs and help redeploy human talent toward more strategic functions like innovation and complex problem-solving (Deloitte, 2023). For emerging economies, autonomous solutions also promise to alleviate labor shortages and infrastructure limitations, expanding market access and competitiveness (EY, 2025).

Amazon’s Robotics and AI-Driven Fulfillment: Amazon has widely implemented autonomous robotics in its fulfillment centers, employing fleets of Kiva robots that navigate warehouse floors autonomously to retrieve items. AI algorithms further optimize the ordering and placement of stock based on historical trends, real-time demand, and proximity to shipping zones (PwC, 2024). By automating repetitive tasks, Amazon reduces human labor requirements while speeding order processing—a vital edge in the ultra-competitive e-commerce market.

JD.com’s Last-Mile Delivery Drones and Vehicles: In China, JD.com has experimented with drones and self-driving delivery vans to expand reach into rural areas and congested urban neighborhoods (KPMG, 2023). Drone routes are mapped using AI-based geographical data, allowing rapid, direct package deliveries in remote terrains. In city environments, autonomous ground vehicles minimize congestion by efficiently navigating crowded streets, thanks to machine learning algorithms that adapt to real-time traffic flows (EY, 2025).

Waymo’s Autonomous Trucking: Waymo, under Alphabet’s umbrella, is adapting its self-driving technology from passenger vehicles to freight transport. By utilizing advanced sensor fusion and AI-based route optimization, Waymo’s trucks aim to reduce dependence on human drivers in long-haul logistics (Deloitte, 2023). The technology can operate continuously, minimizing transit times and labor-related costs. This model holds significant promise for emerging markets grappling with driver shortages and complex logistical networks (Mani, Delgado, and Hazen, 2021).

AI-Integrated Robotic Systems: Emergent robotic platforms leverage computer vision, machine learning, and real-time analytics to perform intricate tasks—such as item picking, sorting, and assembly—without manual oversight (Köhn, 2021). AI-driven inventory management simultaneously processes data on demand fluctuations and capacity constraints, enabling robots to reorder stock or reconfigure warehouse layouts proactively.

Autonomous Vehicles and Drones: Companies like FedEx and UPS are piloting or deploying self-driving trucks and drone fleets for last-mile and even mid-mile deliveries. These vehicles rely on sophisticated sensor arrays, machine learning models, and edge computing capabilities to navigate dynamic road or airspace conditions safely (PwC, 2024). By removing the need for human drivers, businesses can extend service hours and reduce operational costs while improving delivery speed.

IoT-Powered Digital Twins: Digital twins create virtual replicas of physical supply chain environments—warehouses, fleets, and even production lines—fed by continuous IoT sensor updates. AI algorithms interact with these replicas to simulate potential disruptions, test new routing strategies, or forecast demand surges in a consequence-free environment (EY, 2025). This approach allows supply chain managers to optimize flows and resources on the fly, a cornerstone capability in fully autonomous systems (Mani, Delgado, and Hazen, 2021).

Autonomous supply chains offer unique benefits for developing regions, where infrastructure gaps and labor constraints can impede growth. Self-driving fleets alleviate issues related to driver shortages or inconsistent road networks, and automated warehouses reduce the dependency on extensive manual labor (Köhn, 2021). At the same time, digital twin simulations can help smaller companies model best routes and inventory strategies despite limited on-ground data. The net effect is often increased market participation and an accelerated path to global competitiveness.

The trajectory toward autonomy suggests that assisted automation will gradually give way to increasingly self-governing systems (Deloitte, 2023). As AI matures, robots become more dexterous, and IoT data volume explodes, supply chains will automate both physical workflows and cognitive decision-making. Researchers and practitioners emphasize, however, that adopting advanced technologies must go hand in hand with robust cybersecurity measures, ethical guidelines, and regulatory compliance (EY, 2025). Over time, this shift is expected to free up human capital for higher-value tasks and strategic leadership, ushering in a new era of supply chain innovation where speed, precision, and adaptability are paramount.

9.3. The Role of Quantum Computing

Quantum computing is rapidly emerging as a transformative technology for solving the most complex optimization problems in supply chain management. Unlike classical computers that process information in binary bits—either 0 or 1—quantum computers utilize qubits, which can exist in multiple states simultaneously through the principles of superposition and entanglement (Chang and Lee, 2023). By examining vast numbers of possibilities in parallel, quantum computers can tackle computationally challenging tasks at speeds that would be infeasible on traditional hardware. This capability proves especially valuable for supply chain operations characterized by intricate logistics networks, fluctuating consumer demand, and numerous interdependent variables (KPMG, 2023).

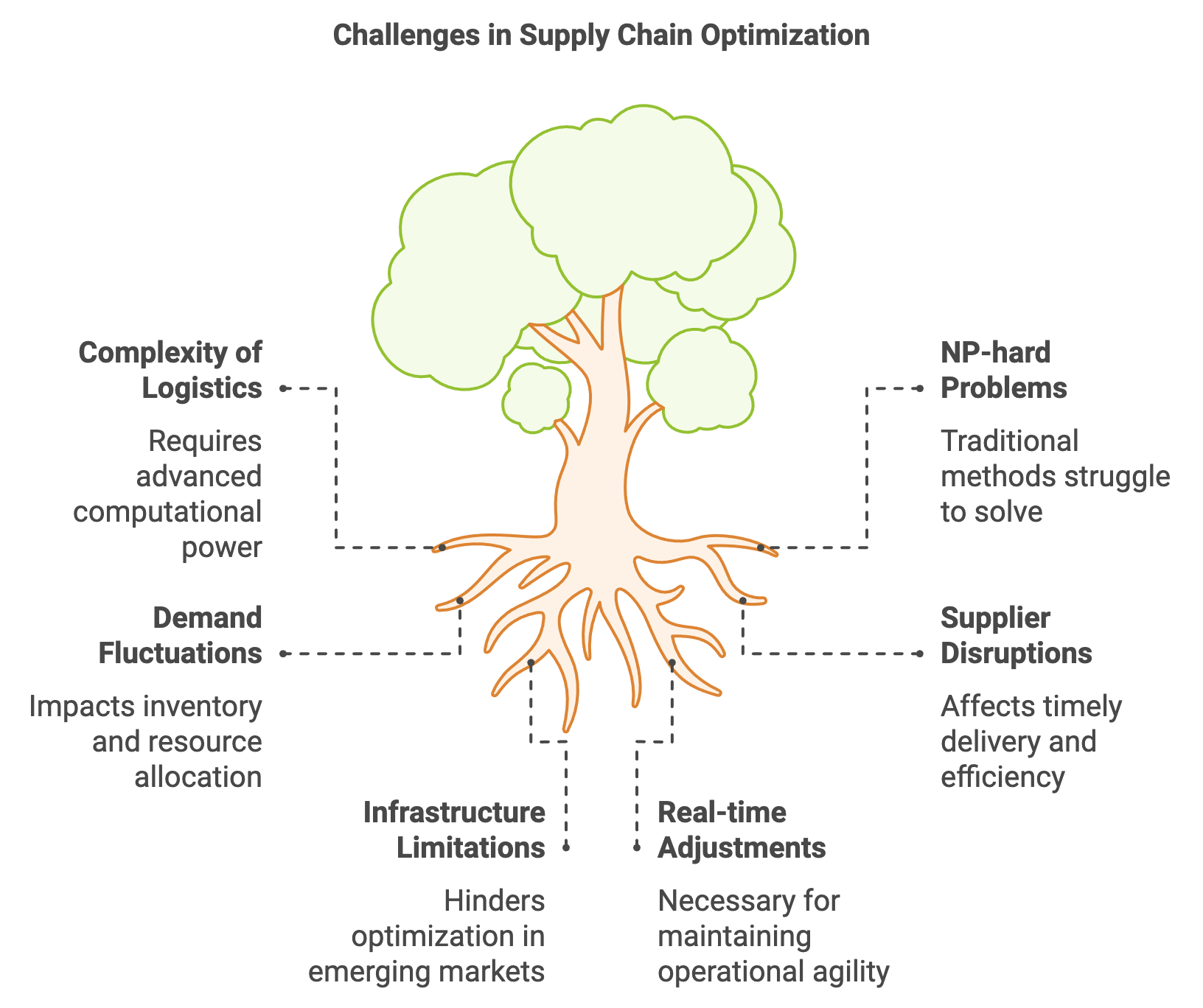

Figure 3: Complexities and challenges in supply chain optimization.

Traditional supply chain optimization problems—such as vehicle routing, resource allocation, and production scheduling—often fall under the umbrella of NP-hard challenges, meaning they require immense computational time to solve optimally (Rodriguez et al., 2022). Quantum computing offers a potential leap forward by evaluating multiple routes, schedules, or inventory configurations simultaneously. This parallelism allows organizations to identify highly efficient solutions faster and more accurately than with conventional methods, especially when real-time factors such as weather, traffic congestion, and supplier reliability must be considered (Deloitte, 2023).

Academically, the intersection of quantum computing and supply chains spans quantum physics, computer science, and operations management, reflecting a growing body of interdisciplinary research (Chang and Lee, 2023). For emerging markets, which often grapple with limited infrastructure and unpredictable disruptions, quantum-enabled optimization can significantly improve resource allocation, reduce inefficiencies, and bolster competitive advantage (EY, 2025).

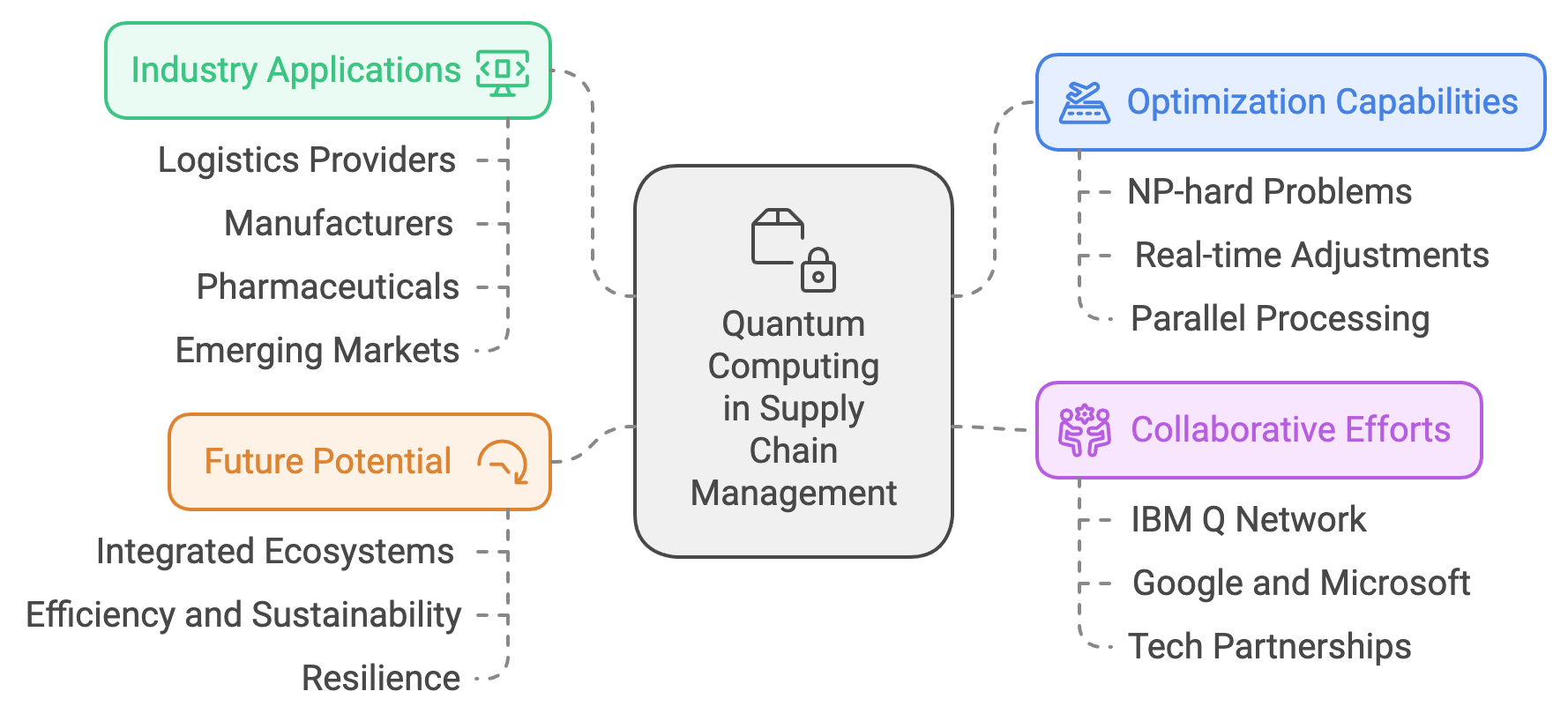

Forward-thinking companies in logistics and manufacturing are already exploring quantum computing’s capacity to enhance supply chain performance. Major players such as DHL and UPS, for instance, have begun experimenting with quantum algorithms to refine route planning and capacity utilization, seeking to reduce delivery times, fuel costs, and carbon emissions (PwC, 2024). In the pharmaceutical sector, organizations leverage quantum computing to streamline cold-chain logistics, ensuring that temperature-sensitive products like vaccines maintain efficacy throughout distribution (Deloitte, 2023).

Tech firms like IBM have accelerated this trend by collaborating with logistics and manufacturing partners under initiatives such as the IBM Q Network. These collaborations aim to address NP-hard optimization problems that exceed the capability of classical computers in real-time settings, including dynamic demand forecasting and multi-tier supplier risk assessment (KPMG, 2023). By pooling resources and domain expertise, these alliances pave the way for practical applications of quantum computing in live supply chain environments.

Quantum computing’s capacity for concurrent scenario evaluation transforms supply chain responsiveness. For instance, a logistics provider can use quantum-based algorithms to simulate multiple distribution paths for last-mile delivery, accounting for real-time fluctuations in road closures or labor availability (Rodriguez et al., 2022). This real-time approach allows immediate route recalibrations and resource reallocation, effectively reducing downtime and cutting operational costs.

Figure 4: Capabilities, Potentials, Applications and Collaborations in Quantum Computing for Supply Chain Optimization.

Additionally, quantum-powered algorithms offer sophisticated simulations of potential supplier disruptions, enabling companies to reoptimize networks swiftly. If a key supplier encounters production delays, the quantum algorithm can propose alternative suppliers or routing strategies, minimizing ripple effects along the chain (Chang and Lee, 2023). This resilience is particularly important in emerging markets, where supply chain shocks—such as infrastructural failures or political instability—may be more frequent and severe (EY, 2025).

A notable trend in quantum computing is the formation of consortia among tech leaders, logistics providers, and manufacturers, aimed at advancing quantum research while contextualizing solutions to real-world supply chain issues (KPMG, 2023). Google, Microsoft, and IBM have each partnered with global logistics giants to develop specialized quantum solutions for route optimization, scheduling, and complex demand forecasting. These ecosystems not only expedite the proof-of-concept stage but also yield industry-focused insights that shape algorithmic designs for maximum operational impact (Deloitte, 2023).

Such collaborations signal a shift toward a quantum-powered future in which supply chains evolve into hyper-efficient, data-rich networks. The results may include minimized lead times, optimized warehouse layouts, and risk-adjusted sourcing strategies—factors that collectively bolster supply chain agility (PwC, 2024). As these pilot projects mature, the lessons learned and algorithms refined will serve as a foundation for broader industry adoption.

Although quantum computing shows great promise, it remains in a nascent stage, with several technical hurdles—such as error correction, qubit stability, and hardware scalability—still under active research (Rodriguez et al., 2022). Moreover, aligning quantum solutions with existing digital infrastructure requires organizational readiness, robust data governance, and collaborative R&D investments (EY, 2025). Nonetheless, the potential efficiency gains, cost savings, and competitive differentiators offered by quantum computing have spurred growing interest among supply chain leaders globally.

In the long term, quantum computing may redefine how supply chains function by enabling continuous, real-time optimization across all nodes of a network. As quantum hardware matures and algorithms evolve, companies in both developed and emerging economies stand to benefit from faster, more accurate decision-making that transcends the computational limitations of conventional systems (KPMG, 2023). For those seeking to stay at the forefront of supply chain innovation, the exploration of quantum computing represents not just an option, but a strategic imperative that will likely reshape the competitive landscape in the years to come (Deloitte, 2023).

9.4. Sustainability and Corporate Social Responsibility (CSR)

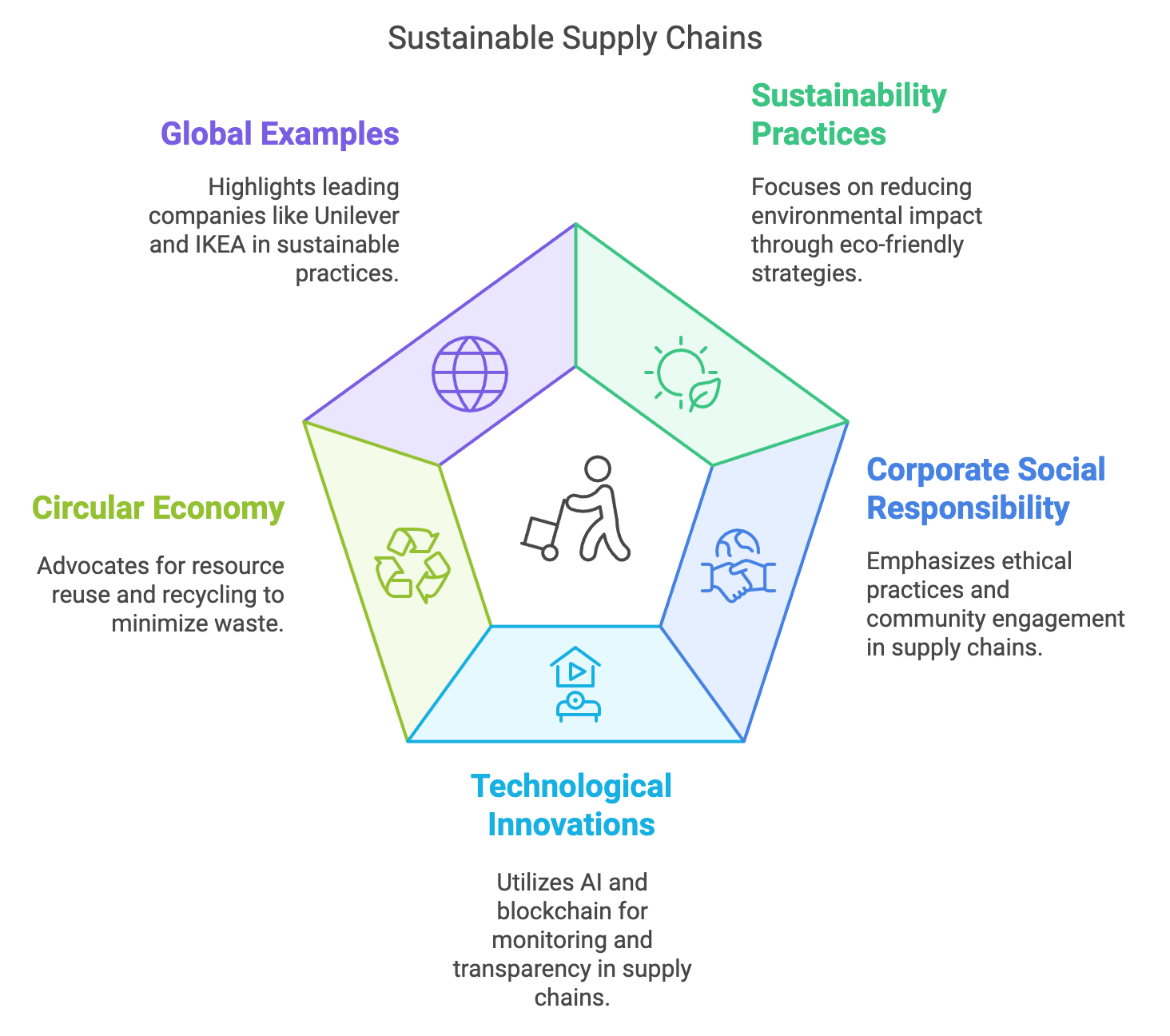

Over the past decade, sustainability and Corporate Social Responsibility (CSR) have become integral to modern supply chain management, reflecting the growing demand for ethical, eco-friendly, and socially responsible operations (Bon, 2021; PwC, 2024). While sustainability prioritizes reduced environmental impact—such as minimized carbon emissions and effective resource utilization—CSR underscores ethical labor practices, equitable community engagement, and broader human rights protections. Taken together, these imperatives drive companies to not only boost efficiency and profitability but also uphold values that support both society and the planet (Deloitte, 2023). This dual focus increasingly shapes how supply chains are designed, operated, and evaluated in today’s global marketplace.

A pivotal aspect of sustainable supply chains is lowering the carbon footprint, a pressing concern amid heightened global awareness of climate change (KPMG, 2023). This endeavor spans energy-optimized manufacturing and logistics processes, cleaner transportation methods, and adoption of renewable energy sources. Another key dimension involves the transition toward circular economy principles, emphasizing resource reuse, recycling, and waste minimization (Bon, 2021). By designing products for durability or utilizing materials that can be remanufactured, companies close the loop on product lifecycles, reducing both environmental strain and reliance on virgin resources. In emerging economies, these initiatives can spark local job creation in recycling and remanufacturing, yielding socio-economic benefits alongside environmental gains.

Figure 5: Sustainable Supply Chains Strategies.

Academic research indicates that implementing sustainable strategies correlates with long-term supply chain resilience. Studies show that companies employing life-cycle assessments and green procurement methods often report improved operational efficiency and brand reputation (Gupta and Singh, 2022). In emerging markets, sustainable practices can be transformative, providing frameworks that support environmental conservation while enhancing market competitiveness (EY, 2025). This alignment with international environmental standards can bolster export opportunities and attract partnerships with multinational firms seeking compliant and transparent suppliers.

While sustainability targets environmental objectives, CSR focuses on ethical responsibilities across labor and community domains (Deloitte, 2023). This includes ensuring fair wages, safe working conditions, and respect for local cultures in supplier facilities. Brands that neglect these responsibilities risk reputational damage, legal liabilities, and consumer backlash—especially in an era where stakeholders scrutinize corporate behavior more than ever (PwC, 2024). Conversely, companies that champion ethical sourcing build resilience through stronger supplier relationships, lower attrition, and an enhanced public image.

Global corporations such as Unilever and IKEA demonstrate how CSR and sustainability converge to guide strategic initiatives. Unilever’s ambition to halve its environmental footprint includes sustainable sourcing of key commodities—like palm oil and tea—while driving socio-economic gains in local farming communities (Bon, 2021). Similarly, IKEA’s commitment to a climate-positive future by 2030 entails the use of renewable materials, energy efficiency in distribution, and product take-back programs that foster circularity. Both exemplify how large-scale businesses merge environmental objectives with social obligations, forging supply chains that garner trust and loyalty from consumers, investors, and regulatory bodies alike (Deloitte, 2023).

In pursuit of deeper sustainability, many companies adopt carbon-neutral goals, seeking to offset or eliminate as many emissions as they produce (Gupta and Singh, 2022). This typically involves both direct actions—like upgrading fleets to electric vehicles or investing in renewable power—and indirect measures, such as purchasing carbon credits for unavoidable emissions (KPMG, 2023). Environmental, Social, and Governance (ESG) frameworks provide standardized metrics for such initiatives, guiding transparent reporting and helping companies benchmark their progress. As consumer and regulatory pressure for climate accountability mounts, carbon-neutral strategies are no longer viewed as optional—particularly in sectors with heavy carbon footprints like logistics, manufacturing, and retail (EY, 2025).

Artificial intelligence is proving instrumental in enabling real-time tracking of sustainability indicators. By analyzing IoT sensor data on fuel consumption, production scrap, or packaging waste, AI platforms identify inefficiencies and recommend targeted improvements (PwC, 2024). Over time, predictive analytics can optimize routes for lower emissions or simulate production changes to minimize energy usage. Such digital tools help companies move beyond reactive “green” measures and proactively embed sustainability in every operational decision.

In industries like fashion or electronics, verifying the ethical origin of raw materials or labor practices is critical for upholding CSR commitments (Deloitte, 2023). Blockchain’s immutable ledgers offer a reliable way to track each product’s history from source to store. Smart contracts encoded within a blockchain can automatically enforce compliance rules, flagging deviations in environmental or labor standards. This technology not only reassures consumers about product authenticity but also simplifies auditing for supply chain partners and regulators (KPMG, 2023).

Efforts to integrate CSR and sustainability often intersect significantly with development goals in emerging regions. Suppliers there might be required to adopt fair labor practices or meet specific environmental milestones to partner with global brands (EY, 2025). While this can initially strain local businesses with limited resources, it ultimately promotes higher standards that improve worker welfare, environmental stewardship, and overall competitiveness. Access to blockchain-based platforms, AI monitoring tools, and ESG frameworks further lowers the barriers for small and medium enterprises (SMEs) to demonstrate compliance and tap into international markets.

Sustainability and CSR are no longer peripheral concerns but central tenets of robust supply chain management. By striving for carbon neutrality, embedding circular economy concepts, and safeguarding worker rights, companies strengthen both resilience and brand credibility (PwC, 2024). High-profile exemplars like Unilever and IKEA show how these practices can align with profitability, while emerging technologies—AI-driven analytics and blockchain traceability—offer unprecedented opportunities to measure, verify, and enhance environmental and social impact (Deloitte, 2023). As both developed and emerging markets evolve, the synergy between sustainability, CSR, and advanced digital solutions sets the stage for supply chains that are efficient, equitable, and future-ready.

9.5. Emerging Technologies and Trends to Watch

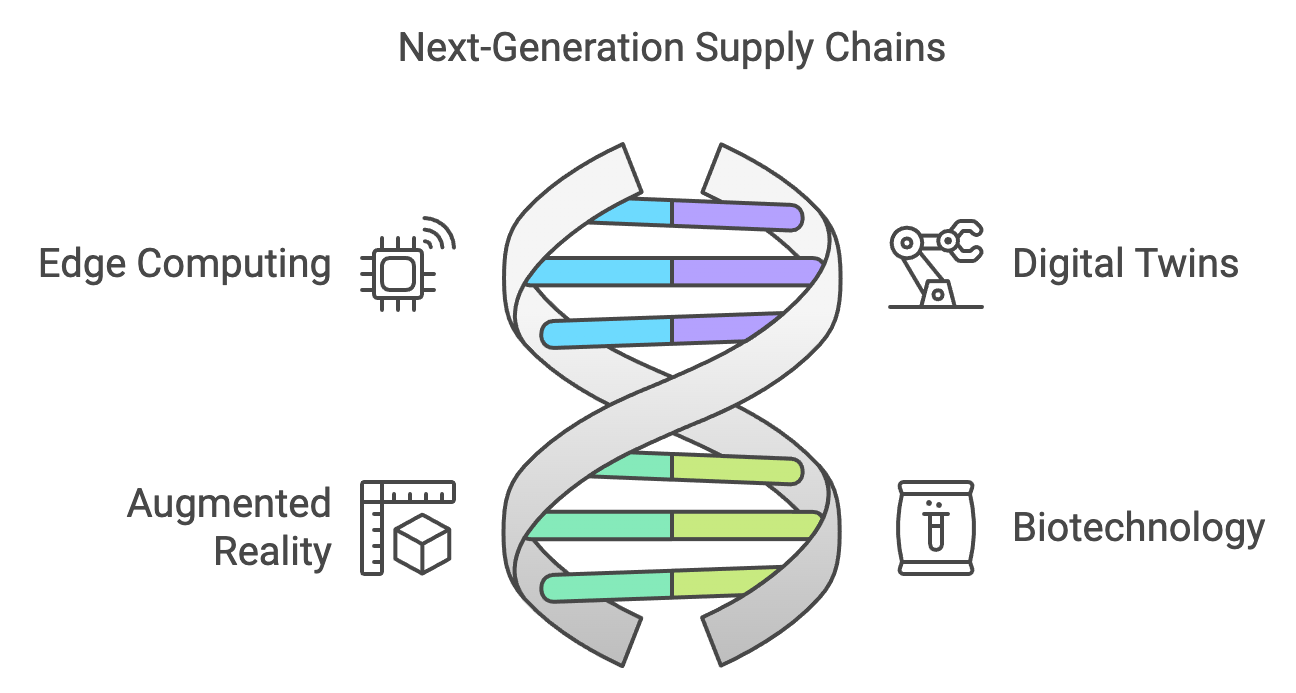

In an era marked by increasingly intricate global supply chains, a host of emerging technologies—ranging from edge computing and digital twins to augmented reality (AR) and biotechnology—are reshaping how companies streamline operations, enhance visibility, and achieve sustainability goals (KPMG, 2023; PwC, 2024). These innovations, often complemented by broader trends like hyperconnectivity and green logistics, are redefining the fundamental architecture of supply chains. As a result, both established and emerging market players can leverage new tools to boost responsiveness, reduce risk, and align with evolving consumer and regulatory demands (Deloitte, 2023).

Edge computing stands out as a critical enabler of responsive supply chain operations. By processing data closer to its point of generation—be it within distribution centers, onboard transport vehicles, or at manufacturing sites—edge computing reduces latency and bolsters localized decision-making (Lu and Chen, 2022). For instance, Amazon employs edge devices across its warehouse networks to rapidly analyze inventory levels and operational metrics, allowing immediate adjustments in order fulfillment and routing (PwC, 2024). This approach curbs reliance on cloud connectivity, a boon for large-scale IoT deployments where constant, high-bandwidth data transmission can be costly or prone to disruption.

Figure 6: Trends in next generation Supply Chains.

Academically, research on edge computing in logistics and manufacturing underscores its potential to accelerate processes such as inventory audits, predictive maintenance, and dynamic routing (Lu and Chen, 2022). In emerging economies, edge solutions can address limited infrastructure by optimizing local resources—an appealing proposition for regions aiming to compete on a global stage without the burden of extensive cloud-based overheads (EY, 2025).

Digital twin technology offers a virtual replica of physical assets or entire supply chain ecosystems, updated continuously through sensor data. This allows companies to run simulations, detect inefficiencies, and test potential changes without disrupting live operations (Zhang et al., 2023). Firms like Airbus use digital twins to synchronize and optimize production lines, tracking components in real-time to predict maintenance needs and minimize downtime (Deloitte, 2023).

Emerging markets can also capitalize on digital twins by modeling resource constraints or infrastructure gaps and testing mitigation strategies. This method fosters more strategic decision-making, whether the goal is efficient resource allocation or ramping up production with minimal risk. Researchers highlight digital twins as a vital tool for operational resilience, helping businesses anticipate market shifts or disruptions with enhanced agility (Zhang et al., 2023).

Augmented reality is swiftly gaining traction in logistics, manufacturing, and workforce development. By overlaying digital information onto real-world environments, AR applications streamline tasks such as order picking, inventory checks, and equipment assembly (KPMG, 2023). DHL’s deployment of AR glasses, for instance, significantly reduced search times for items in warehouses, boosting productivity and minimizing errors (PwC, 2024). Beyond routine processes, AR also serves as an interactive training platform, allowing employees to practice new procedures in a lifelike, risk-free setting.

Academic studies confirm AR’s capacity to shorten onboarding periods, improve task accuracy, and relieve cognitive load on workers (Deloitte, 2023). In emerging economies, where training resources may be limited, AR offers a cost-effective avenue to scale up workforce skills, enhancing both quality and operational efficiency.

Biotechnology represents a frontier in developing eco-friendly materials and manufacturing practices. Industries ranging from fashion to packaging are exploring bio-based alternatives—like lab-grown leather or biodegradable polymers—to diminish environmental impact (EY, 2025). For example, apparel brands have begun sourcing bioengineered textiles that cut down on water usage and chemical runoff, aligning with circular economy principles aimed at reducing waste and promoting reuse (KPMG, 2023).

Biotechnology’s significance transcends high-profile consumer goods; it extends to bio-based feedstocks for chemical production, helping industries reduce reliance on fossil fuels. This approach can be especially beneficial for emerging economies, enabling more sustainable export products that comply with global environmental standards.

Supply chains are evolving into decentralized networks where continuous data exchange underpins every link—from suppliers and manufacturers to logistics providers and end consumers (Lu and Chen, 2022). This hyperconnectivity distributes decision-making power and mitigates single points of failure. Blockchain technology often underlies data sharing in these decentralized models, ensuring integrity, transparency, and real-time collaboration (Deloitte, 2023).

Companies across sectors are seeking to reduce their carbon footprint through cleaner transportation options, route optimization, and emission offset initiatives (PwC, 2024). The urgency for sustainability has catalyzed investments in electric vehicle fleets, alternative fuels, and innovative packaging solutions. Green logistics initiatives bolster brand reputation, comply with tightening environmental regulations, and meet consumer expectations for eco-responsible behavior (EY, 2025).

Technologies such as edge computing, digital twins, augmented reality, and biotechnology are not merely incremental enhancements; they represent foundational shifts that enable supply chains to become more agile, resilient, and environmentally responsible (Zhang et al., 2023). Companies like Amazon, Airbus, DHL, and forward-thinking fashion or consumer goods brands exemplify how these innovations translate into tangible operational gains—from real-time inventory updates to minimized waste and carbon emissions (KPMG, 2023). Meanwhile, macro trends like hyperconnectivity, decentralization, and green logistics amplify these technological impacts, propelling supply chains into a new era of digital and sustainable efficiency. As such, both global powerhouses and emerging market players have vital incentives to harness these evolving tools, ultimately shaping a more intelligent, equitable, and eco-conscious global supply chain ecosystem (Deloitte, 2023).

9.6. Conclusion and Further Learning

In conclusion, the future of smart supply chains will be shaped by a range of groundbreaking technologies that enable businesses to operate with greater efficiency, transparency, and sustainability. AI, blockchain, 5G, and quantum computing will be at the forefront of this transformation, driving innovation in logistics, warehousing, and supply chain optimization. Companies that embrace these technologies will gain a competitive edge, while those that resist risk being left behind. As the focus on sustainability and ethical practices grows, the role of CSR in supply chains will become increasingly important, further influencing the design and operation of tomorrow's global supply networks.

The future of supply chains is being shaped by groundbreaking technologies that promise to revolutionize the way businesses operate. By diving into these prompts, you will gain a deeper understanding of the transformative power of AI, blockchain, quantum computing, and other emerging technologies. These innovations are not only improving efficiency and transparency but also driving sustainability and ethical practices across global supply networks.

In what ways can AI revolutionize decision-making processes in supply chains, particularly through the application of advanced predictive analytics, real-time demand forecasting, and dynamic inventory management, and how can AI help companies optimize resource allocation in response to market fluctuations?

What are the core advantages of using blockchain technology to secure and verify transactions in global supply chains, and how does it enhance transparency, traceability, and fraud prevention across complex, multi-tiered networks where product authentication and compliance are critical?

How will 5G technology transform the efficiency of data transfer and real-time monitoring in logistics, warehousing, and transportation, and what are the primary technical, infrastructural, and regulatory challenges that need to be addressed to enable large-scale implementation of 5G in supply chain ecosystems?

What are the most promising applications of autonomous robots in warehousing operations, particularly in tasks such as order picking, inventory management, and material handling, and how will these advancements affect labor dynamics, operational efficiency, and cost structures in supply chain management?

How can businesses strategically transition from assisted automation to fully autonomous supply chains, and what role will AI, IoT, machine learning, and robotics play in achieving end-to-end automation across procurement, production, logistics, and last-mile delivery?

What specific optimization problems, such as route planning, resource allocation, and demand variability, can quantum computing address in supply chains, and how does quantum computing’s ability to process vast amounts of data at unprecedented speeds provide a competitive edge in solving complex supply chain challenges?

How does quantum computing outperform classical computing when solving NP-hard problems like multi-variable route optimization and demand forecasting in real time, and what potential does this hold for drastically improving supply chain efficiency, responsiveness, and scalability in high-demand industries?

In what ways can AI and blockchain technologies work in tandem to support sustainability initiatives in supply chains, such as reducing carbon footprints, optimizing energy consumption, and verifying ethical sourcing, and how can they help organizations meet global environmental standards and ESG goals?

What are the critical factors for integrating circular economy principles into supply chains, and how can AI-driven platforms and advanced analytics optimize waste reduction, recycling, and resource recovery processes to enable closed-loop supply chain models that reduce environmental impact?

How can blockchain technology improve transparency and accountability in sustainability practices, particularly in verifying compliance with ethical sourcing, reducing the environmental impact of production, and ensuring accurate tracking of emissions and waste in global supply chains?

What are the key advantages of leveraging digital twin technology to simulate, monitor, and optimize supply chain networks in real time, and how can businesses use these virtual models to enhance decision-making, identify bottlenecks, and improve overall operational efficiency across global supply chains?

How can edge computing reduce latency and improve real-time data processing in supply chains, especially in highly dynamic environments where rapid decision-making is critical, and what are the key challenges in deploying edge computing at scale to support predictive analytics, IoT devices, and automated systems?

What are the practical applications of augmented reality (AR) in logistics and supply chain management, particularly in employee training, real-time inventory tracking, and equipment maintenance, and how does AR technology enhance operational efficiency, worker safety, and process accuracy in these environments?

How can AI and IoT technologies be integrated to create a more agile and responsive supply chain capable of adapting to real-time changes in demand, inventory levels, and disruptions, and how can this integration drive improvements in overall supply chain visibility and decision-making accuracy?

How is biotechnology influencing the development of sustainable materials in industries like fashion, manufacturing, and consumer goods, and what are the implications of these innovations for reducing the environmental impact of supply chains through eco-friendly production and supply chain practices?

What are the key technical and operational challenges that businesses face in implementing quantum computing solutions for supply chain optimization, and how can organizations overcome barriers related to cost, scalability, and quantum algorithm development to gain a competitive advantage?

How can 5G technology enable the widespread deployment of autonomous vehicles and drones in supply chain logistics, particularly in last-mile delivery, and what impact will this have on operational efficiency, delivery speed, and cost-effectiveness in industries with complex logistics needs?

What ethical considerations must businesses address as they transition to fully autonomous supply chain operations, particularly in terms of labor displacement, data privacy, and the equitable distribution of the benefits of automation, and how can companies ensure responsible and transparent implementation of these technologies?

How can AI-driven platforms, combined with predictive analytics, enhance supply chain resilience by forecasting demand fluctuations, predicting external disruptions, and enabling proactive risk management, particularly in global supply chains that face frequent and unpredictable challenges?

What long-term strategic benefits can businesses expect from adopting advanced technologies like AI, blockchain, and quantum computing in their supply chains, and how can these innovations drive the future of global trade by improving efficiency, reducing risks, enhancing sustainability, and fostering transparency across industries?

Let these prompts inspire you to think critically and explore how you can apply these technologies to build smarter, more resilient, and future-proof supply chains. The journey toward the future starts with curiosity and a willingness to embrace change—so start learning and lead the transformation!

Comments