Chapter 7

Human and Collaborative Factors in Smart Supply Chains

"Technology is just a tool. In terms of getting the kids working together and motivating them, the teacher is the most important." — Bill Gates, Co-founder of Microsoft

Chapter 7 focuses on the critical role that human intelligence and collaboration play in the advancement of smart supply chains. It examines how human expertise complements automation, the significance of cross-industry partnerships in building resilient digital ecosystems, and the importance of upskilling the workforce to manage AI-powered operations. The chapter also explores how leadership in a data-driven supply chain era requires balancing technological innovations with human oversight, fostering a culture of collaboration, and enabling data-driven decision-making to navigate the complexities of modern supply chains.

7.1. The Role of Human Intelligence

In an age increasingly defined by automation, robotics, and artificial intelligence (AI), the importance of human intelligence in supply chain management endures. While machine-driven systems excel at analyzing large volumes of data and performing repetitive tasks, human intelligence adds the critical dimensions of creativity, judgment, and ethical insight (Zhang, Zhang, and Li, 2023). For many organizations, advanced AI tools and algorithms can accelerate decision-making, but they still rely on human oversight to interpret ambiguous information, manage strategic trade-offs, and handle unprecedented disruptions (PwC, 2023). Thus, far from being displaced, the human element in supply chain operations is growing in significance, offering adaptability and intuition that automated systems have yet to replicate.

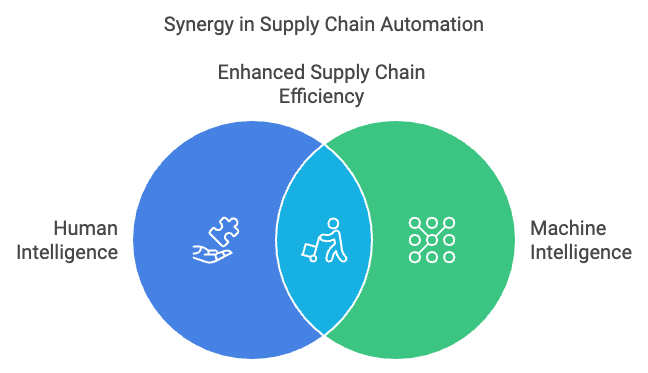

Figure 1: Machine intelligence with human in the loop.

The collaborative framework that fuses human expertise with automated processes is often described as “human-in-the-loop” (HITL). Under this model, humans supervise and, when necessary, intervene in AI-driven systems to address exceptions, interpret complex data, or make ethical judgments (KPMG, 2022). For instance, AI-based route optimization tools can efficiently chart delivery paths, but unexpected events—such as extreme weather or regional political unrest—may demand human judgment to promptly reconfigure logistics flows. In these scenarios, human operators excel at reacting to novel problems, integrating broader context, and weighing intangible factors like corporate social responsibility or consumer trust (Ge, Zhao, and Jiang, 2021).

The relevance of human-in-the-loop systems is particularly evident in emerging markets, where infrastructure conditions can vary greatly. Even as local players adopt automation to improve cost-efficiency and speed, human oversight becomes pivotal to navigating context-specific challenges, such as seasonal variations in rural road conditions or erratic power supplies (EY, 2025). By preserving human autonomy within automated workflows, these markets can adapt more deftly to unanticipated disruptions, thus mitigating potential losses and operational downtime.

Rather than framing AI as a replacement for human roles, many experts advocate for “augmented intelligence,” an approach designed to enhance human decision-making (Chen et al., 2022). AI can generate insights, predictions, and potential solutions, but it is ultimately human intelligence that contextualizes these findings within broader organizational goals. In inventory management, for example, an AI system may predict imminent stockouts based on sales patterns, yet a human manager can decide how best to allocate limited inventory across multiple distribution channels, accounting for brand reputation, key customers, or regulatory constraints (Deloitte, 2021).

High-profile companies illustrate the effectiveness of this synergy. Amazon, known for its extensive automation—from robotic pickers to advanced forecasting algorithms—still relies on warehouse associates for quality checks, issue resolution, and handling unique customer requests. Meanwhile, Tesla complements its automated manufacturing lines with human technicians trained to spot irregularities, make real-time modifications, and address specialized engineering challenges (PwC, 2023). This coexistence of AI-driven production with human oversight helps these firms remain agile in the face of fluctuating component supplies, evolving safety regulations, and shifting consumer preferences.

A key advantage of human intelligence lies in its adaptability and capacity for ethical or value-based decision-making—factors that pure automation often struggles to accommodate (Kroop and Ristic, 2024). Fully automated systems can be vulnerable to unforeseen crises or data anomalies if their algorithms have not been exposed to similar training scenarios. By contrast, humans can rapidly recalibrate strategies based on real-time feedback and contextual insights. This capability is indispensable during high-stakes situations such as pandemic-related shutdowns or global trade disputes, where standard predictive models may not suffice (EY, 2025).

Moreover, certain supply chain decisions demand ethical considerations that extend beyond operational metrics. Allocating scarce resources during emergencies or setting sustainable sourcing priorities involves moral trade-offs that algorithms are ill-equipped to handle autonomously (Chen et al., 2022). Human professionals can integrate stakeholder values, corporate social responsibility guidelines, and nuanced cultural sensitivities into decisions, preserving a level of corporate citizenship and accountability that consumers increasingly demand (Deloitte, 2021).

The potential benefits of human-in-the-loop and augmented intelligence are especially pronounced in emerging economies, where supply chain infrastructures can be fragmented and subject to volatility (KPMG, 2022). For instance, AI-driven inventory management may guide procurement strategies, but local supply managers must calibrate that guidance against issues like unreliable road networks or fluctuating local regulations. This joint human-AI collaboration not only safeguards against purely algorithmic blind spots but also nurtures operational resilience.

An illustration can be found in African e-commerce startups that use AI for route optimization yet retain human dispatchers to reroute vehicles when facing impassable roads or sudden market shifts. This hybrid approach provides both efficiency gains and the flexibility necessary to address local nuances, enabling smaller enterprises to compete effectively with established global brands (EY, 2025).

While AI and automation continue to revolutionize supply chain operations, human intelligence remains indispensable. By blending automated efficiency with human adaptability, organizations can navigate complex logistical environments, respond to emergent disruptions, and uphold ethical standards (PwC, 2023). Whether through human-in-the-loop frameworks or augmented intelligence platforms, the synergy between human and machine learning drives transformative gains in productivity, agility, and resilience (Chen et al., 2022). As supply chains evolve further, the most competitive and sustainable models will be those that harness the strengths of both automation and human expertise—ensuring that innovation does not come at the expense of judgment, empathy, or strategic vision.

7.2. Cross-Industry Collaboration

Cross-industry collaboration has emerged as a critical strategy for cultivating resilient, adaptive, and technology-enabled supply chains. In an era where global disruptions—from pandemics to geopolitical tensions—can ripple across multiple industries, no single organization can independently manage all potential risks and complexities (KPMG, 2022). By uniting under shared objectives, companies from diverse sectors leverage complementary strengths, access new markets, and drive collective innovation. Recent studies underscore that robust cross-industry partnerships foster greater supply chain agility and encourage novel solutions that transcend traditional industry silos (Singh and Gupta, 2021). These collaborations not only facilitate resource sharing and risk diversification but also position stakeholders to capitalize on advanced digital tools—such as IoT, AI, and blockchain—to modernize and streamline end-to-end operations (PwC, 2024).

The growing interdependence of global supply networks highlights the value of collaboration as a means of addressing the inherent volatility of contemporary markets (Lee and Kim, 2023). Traditional, siloed approaches often fail to accommodate the complexity of modern logistics, where automotive manufacturers rely on semiconductor technology, healthcare providers seek specialized cold-chain logistics, and e-commerce giants depend on analytics-driven innovation (Reddy, 2024). By forming alliances with entities in different sectors, companies can pool insights, share infrastructure, and create more holistic strategies for dealing with uncertain demand, tight delivery windows, and evolving regulatory frameworks (EY, 2025).

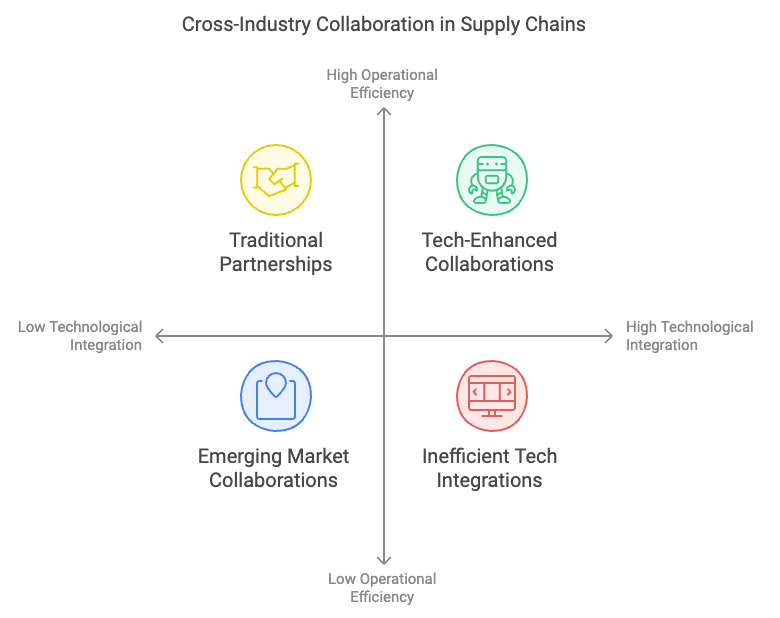

Figure 2: Cross-industry collaboration strategy in supply chains.

In emerging economies, cross-industry partnerships can be particularly transformative, enabling local firms to overcome infrastructure gaps and technology shortages. For instance, a manufacturing enterprise in Southeast Asia might collaborate with a global tech provider to develop IoT-based tracking, thereby improving visibility over goods in transit. This shared knowledge and resource model fosters mutual learning and can expedite local companies’ ascension to global supply chain standards (Singh and Gupta, 2021).

Technological integration remains a linchpin for effective cross-industry collaboration. Joint ventures that incorporate AI-driven analytics, blockchain, or IoT sensors can significantly enhance transparency, data sharing, and operational efficiency (Lee and Kim, 2023). For example, blockchain-based consortiums allow disparate stakeholders to securely exchange information and authenticate transactions—from agricultural cooperatives verifying the provenance of produce to pharmaceutical firms ensuring the integrity of temperature-sensitive vaccines (Deloitte, 2023).

AI-powered platforms play a similarly impactful role by consolidating data from multiple sources—demand signals, weather forecasts, global shipping updates—to produce predictive analytics. Such tools enable collaborative forecasting and resource optimization across different industries, mitigating stockouts and reducing excess inventory (PwC, 2024). In practice, a joint effort between an electronics producer and a major logistics provider could combine data on semiconductor availability with real-time shipping capacity analytics, leading to better-aligned production schedules and more reliable delivery windows (KPMG, 2022).

Major corporations have exemplified how cross-industry partnerships can generate comprehensive supply chain solutions. Apple’s longstanding collaboration with Foxconn underscores the benefits of integrated manufacturing and logistics: Apple capitalizes on Foxconn’s electronics expertise and large-scale manufacturing capacity, while Foxconn gains stable, high-volume production orders and opportunities to refine its operational efficiencies (EY, 2025). This synergy allows both parties to respond swiftly to fluctuations in consumer demand and to collaboratively tackle issues such as component shortages or sudden shifts in global trade policies (Reddy, 2024).

Another instance is Walmart’s alignment with Google to incorporate voice-activated shopping via AI-driven platforms. This partnership merges Google’s cutting-edge voice recognition and predictive analytics with Walmart’s extensive retail and distribution network, crafting a seamless omnichannel experience for customers (PwC, 2024). Beyond augmenting customer convenience, the initiative strengthens Walmart’s supply chain by leveraging Google’s data analytics to anticipate purchasing trends and optimize inventory distribution.

In the automotive sector, manufacturers often team up with tech companies to harness real-time data analytics, enabling tighter coordination between production schedules and upstream supply availability (KPMG, 2022). Meanwhile, in healthcare, pharmaceutical firms partner with specialized logistics providers—combining advanced IoT monitoring devices, robust data platforms, and curated distribution strategies to ensure sensitive products (like vaccines) maintain potency throughout transit (Lee and Kim, 2023). These cross-industry engagements not only lower costs and reduce lead times but also elevate overall service reliability and consumer trust.

Risk Diversification: By unifying businesses from different industries, collaborations distribute the exposure to financial, operational, and reputational risks more evenly. In times of crisis—such as natural disasters or raw material shortages—partners can jointly source alternatives or pivot to new models more rapidly (Deloitte, 2023).

Resource and Expertise Sharing: Cross-industry consortia foster a dynamic exchange of skills, capabilities, and infrastructures. This pooling of resources supports faster R&D cycles and encourages more adaptive supply chain practices (Singh and Gupta, 2021).

Enhanced Transparency and Trust: Implementing technologies like blockchain or shared cloud platforms promotes visibility across the supply chain. Stakeholders can monitor product journeys in real time, ensuring authenticity and compliance with regulations, which is especially crucial in sectors such as food safety and pharmaceuticals (Reddy, 2024).

Innovation Ecosystems: Partnerships that align digital innovators with traditional manufacturers accelerate the development of new products and services. This cross-pollination of ideas broadens the scope of innovation and can lead to pioneering approaches in design, production, or last-mile delivery (EY, 2025).

Cross-industry collaboration stands out as a powerful driver of agility and resilience in the modern supply chain environment. By integrating advanced technologies, aligning strategic goals, and pooling resources across multiple sectors, companies can manage risks more effectively, adapt to shifting demands, and capitalize on emerging market opportunities (PwC, 2024). Whether optimizing vaccine distribution through blockchain consortia or merging e-commerce platforms with voice-activated AI, these collaborative models illustrate the transformative potential of working across boundaries. As global competition intensifies and supply chain networks grow more complex, the ability to collaborate with diverse partners will be a cornerstone of sustained competitiveness and innovation in the digital era (Lee and Kim, 2023).

7.3. Training and Upskilling the Workforce

In the rapidly evolving landscape of digital supply chains, developing a skilled workforce has become essential to maximize the potential of AI, IoT, and advanced analytics. Traditional logistics expertise no longer suffices; employees must now be adept at interpreting data, managing AI-driven systems, and overseeing automated processes (Chang and Zhang, 2022). As more companies integrate advanced technologies into their operations, the workforce’s ability to adapt and continuously learn has a direct impact on supply chain resilience and agility (KPMG, 2023). Upskilling initiatives not only allow organizations to stay competitive but also enable them to respond effectively to emergent risks and opportunities in an increasingly complex global marketplace (PwC, 2024).

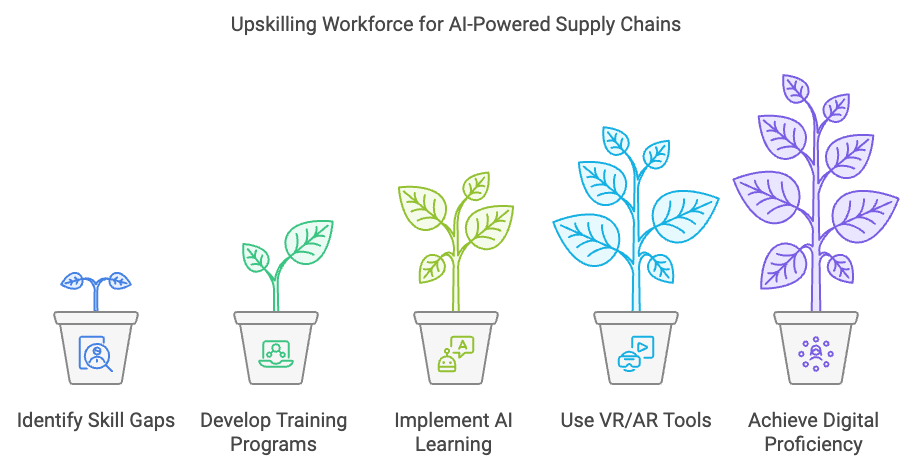

Figure 3: Upskilling workforce is critical in smart supply chains.

The advent of AI, automation, and real-time analytics has fundamentally changed the role of human workers. Instead of merely executing repetitive tasks, employees must harness skills like critical thinking, data analysis, and decision-making informed by predictive models (Gopal et al., 2021). This shift underscores the growing need for interdisciplinary knowledge spanning data science, supply chain management, and cybersecurity. As AI systems become more integrated, workers must also learn to monitor digital tools, diagnose errors, and implement risk mitigation strategies when anomalies or disruptions occur (Deloitte, 2022). In emerging markets, where digitalization may be at an earlier stage, strategic upskilling allows companies to leapfrog older methodologies and embrace cutting-edge practices, thereby expanding their global competitiveness (EY, 2025).

Companies such as Siemens and DHL illustrate how structured training programs can bridge the gap between technological investment and effective implementation. Siemens has established multifaceted courses that combine theoretical instruction—covering subjects like machine learning principles and predictive maintenance—with hands-on experience in simulated or real factory settings (Chang and Zhang, 2022). By immersing employees in practical use cases, Siemens ensures that newly acquired skills translate into operational improvements.

DHL, meanwhile, has introduced digital learning pathways focused on AI-based route optimization, robotic process automation, and data-driven inventory forecasting (KPMG, 2023). In addition to online modules, DHL uses on-site coaching where experts mentor employees through live scenarios, refining both technical proficiencies and soft skills like collaboration and problem-solving. Such blended learning formats expedite the assimilation of AI-enabled technologies into daily supply chain tasks.

Universities and technical institutes increasingly offer specialized curricula and certifications in AI-driven logistics and supply chain analytics. Collaborative arrangements with corporate partners—ranging from internships to co-designed coursework—equip students with practical skills before they enter the job market (Gopal et al., 2021). These partnerships not only facilitate immediate industry relevance in academic programs but also create pipelines of talent ready to manage and evolve digital supply chain ecosystems upon graduation (PwC, 2024).

In emerging markets, these alliances can be even more impactful by addressing local skill gaps and promoting knowledge transfer from multinational corporations and research institutions. Joint ventures may revolve around setting up specialized AI labs or subsidized training for small and medium-sized enterprises eager to digitize their supply chain processes (EY, 2025). Over time, this collaboration fosters a virtuous cycle, where workforce development strengthens the regional supply chain infrastructure, in turn attracting more global investment and technological innovation.

The exponential growth of digital supply chains has catalyzed the adoption of advanced training modalities, including AI-driven learning platforms and immersive virtual or augmented reality (VR/AR) simulations (Santos et al., 2022). AI-enabled training systems can personalize learning pathways based on individual skill assessments, providing targeted modules that help employees quickly fill knowledge gaps. These platforms may also incorporate real-time analytics on learner performance, suggesting additional resources or practice exercises when needed (Deloitte, 2022).

VR/AR approaches allow workers to practice complex tasks in a controlled, low-risk environment. For instance, logistics personnel can rehearse the operation of autonomous picking robots or experiment with digital warehouse management systems in simulated scenarios (Gopal et al., 2021). By enabling safe, hands-on interaction with AI-automated machinery, these immersive tools build employee confidence and mitigate errors once new processes are deployed at scale. For emerging markets with limited physical training facilities, VR/AR can deliver highly scalable training solutions without imposing excessive infrastructure costs (EY, 2025).

As AI models and logistics technologies evolve, a one-time training initiative is seldom sufficient. Ongoing professional development—through refresher courses, certifications, and cross-functional workshops—ensures the workforce remains proficient in newly released tools and practices (Santos et al., 2022). Continuous learning fosters a culture where employees proactively adapt to technological shifts rather than viewing them as threats. This mindset, in turn, drives innovation within the supply chain and heightens organizational resilience in the face of volatility (PwC, 2024).

Ultimately, effective upskilling programs serve not only the immediate operational demands of digital transformation but also the long-term strategic goals of growth and competitiveness. By equipping personnel with the technical acumen and problem-solving abilities required in AI-driven environments, companies can sustain higher levels of performance, reduce downtime caused by skill shortages, and bolster their capacity to pivot in rapidly changing market conditions (Deloitte, 2022). When human talent complements machine capabilities, the supply chain becomes more than a cost center—it evolves into a strategic asset for resilience and value creation.

7.4. Redefining Leadership in the Smart Supply Chain Era

As supply chains become increasingly automated and data-driven, the role of leadership is undergoing a significant transformation. Traditional models, which often revolved around operational oversight and cost management, must now incorporate advanced analytics, AI, and collaborative decision-making to remain competitive (EY, 2025). Leaders no longer focus solely on improving short-term efficiencies; instead, they must foster an organizational culture that balances the power of technology with the creativity and ethical oversight of human teams (PwC, 2024). This new paradigm demands the ability to interpret data, inspire innovation, and build agile structures capable of anticipating and mitigating disruptions.

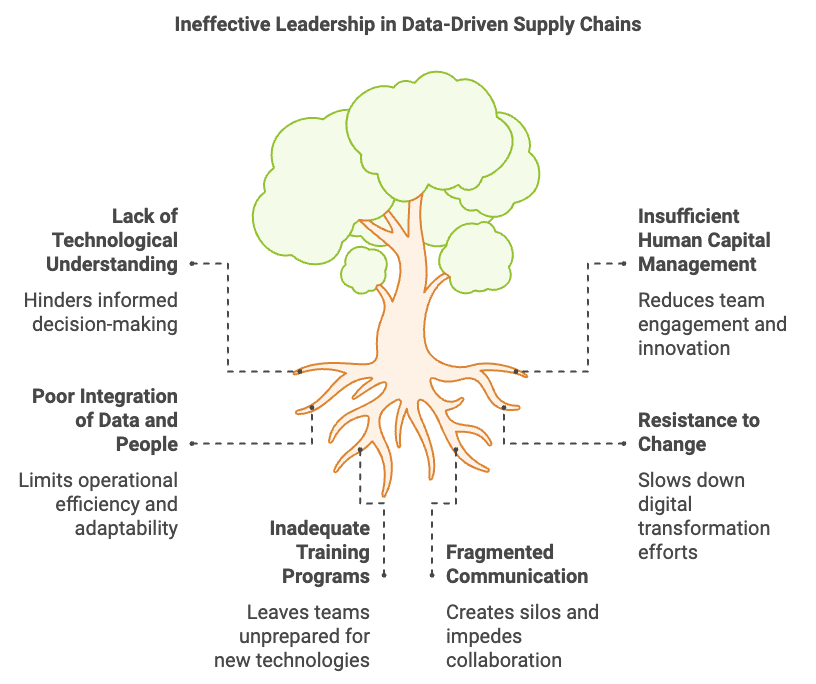

Figure 4: Key challenges in data-driven leadership.

Data-driven leadership centers on leveraging analytics, AI-driven insights, and real-time information to guide decision-making. By examining patterns in inventory levels, transportation logistics, or customer demands, leaders gain a holistic view that transcends traditional gut-feel approaches (Deloitte, 2023). Such data-informed strategies are particularly critical during periods of market volatility or global crises, allowing organizations to pivot swiftly and allocate resources more effectively. Nevertheless, data alone cannot address every nuance. Leaders who excel in this environment seamlessly integrate data insights with human judgment, ensuring that ethical considerations and creative problem-solving are not overshadowed by algorithmic outputs (Bai, Zhong, and Wang, 2021).

In emerging markets, data-driven leadership offers a path for companies to overcome infrastructural hurdles and resource constraints. Real-time analytics can help pinpoint bottlenecks and guide strategic investments in critical areas, while AI-powered forecasting helps optimize production schedules despite uncertain demand patterns (KPMG, 2022). These advantages can significantly enhance local competitiveness, enabling businesses to compete globally by creating more resilient and responsive supply networks.

Global enterprises such as Microsoft and Procter & Gamble (P&G) provide salient examples of how data-driven leadership can reshape supply chain operations. Microsoft employs predictive analytics and AI across its supply chain to anticipate demand fluctuations, manage inventory levels, and rapidly adjust to changing trade policies or local regulations (PwC, 2024). Crucially, Microsoft’s leadership team works to embed these analytics into the company culture, encouraging various departments—beyond supply chain and logistics—to engage with data insights and identify cross-functional improvements.

P&G similarly harnesses machine learning and real-time data to refine demand forecasting, optimize distribution strategies, and balance inventory across its extensive global network (Bai, Zhong, and Wang, 2021). During the COVID-19 pandemic, the ability to integrate AI-driven insights with human judgment enabled P&G to respond promptly to sudden shifts in consumer behavior, ensuring product availability where it was needed most. Equally significant, P&G’s leadership prioritizes a culture of innovation and teamwork, reinforcing the notion that data insights are a catalyst for proactive collaboration, rather than a top-down directive.

Recent technological advances are changing not just how data is collected, but how leaders interpret and act upon it. AI-driven decision-support systems, for instance, can absorb vast quantities of operational information—ranging from raw material availability to real-time shipping routes—and convert them into actionable recommendations (Deloitte, 2023). These platforms free leaders to concentrate on strategic imperatives, such as expanding into new markets or developing novel product lines, while routine data crunching becomes automated.

Collaborative leadership platforms are another powerful tool, integrating AI analytics with human expertise to present leaders with a comprehensive, real-time snapshot of supply chain performance. By centralizing metrics like warehouse throughput, supplier lead times, and quality control parameters, these systems help managers identify risks and opportunities in near-real time (EY, 2025). Leaders can then convene cross-functional teams to brainstorm solutions, ensuring that on-the-ground insights inform final decisions. This synergy between technology and human intelligence proves particularly valuable in emerging markets, where unique cultural and regulatory nuances require a more adaptive, human-centric approach (KPMG, 2022).

While technology provides essential tools, leadership remains the linchpin in ensuring successful adoption and integration. Data-driven leaders must champion transparency, encouraging employees to share insights, question assumptions, and engage with analytics platforms (Bai, Zhong, and Wang, 2021). In settings where digital infrastructure is still developing, leaders also play a pivotal role in guiding workforce training and skill development, ensuring that employees can interpret and operationalize the insights generated by AI.

Moreover, ethical considerations increasingly shape data-driven leadership. As supply chains become more reliant on algorithms for decision-making, leaders must maintain vigilance over areas like bias, privacy, and fairness. This requirement extends to emerging markets, where local regulations and norms may necessitate additional scrutiny of automated processes. By deliberately shaping policies and frameworks that uphold ethical standards, leaders can mitigate potential risks while maintaining trust among employees, stakeholders, and consumers (PwC, 2024).

Redefining leadership in the smart supply chain era involves blending technology, human insight, and a forward-thinking culture. Leaders who fully embrace data-driven methods and foster cross-functional collaboration can orchestrate supply chains that are agile, customer-centric, and robust in the face of global uncertainty (Deloitte, 2023). At the same time, these leaders recognize the indispensable role of human creativity and ethical judgment—elements that cannot be replicated by algorithms alone. By marrying AI-driven insights with people-focused strategies, today’s supply chain visionaries craft resilient, innovative organizations prepared to excel in a rapidly evolving marketplace.

7.5. Conclusion and Further Learning

In conclusion, while automation and AI are transforming the operational aspects of supply chains, the role of human intelligence, collaboration, and leadership remains indispensable. Humans are key to managing the strategic aspects of these advanced systems, ensuring flexibility and creativity in complex situations. As organizations increasingly adopt AI and digital tools, fostering cross-industry collaboration and upskilling the workforce will be essential for maintaining competitiveness and resilience in the smart supply chain landscape.

Exploring the following prompts will allow you to dive deeper into the intersection of human intelligence and technological innovation in smart supply chains. By engaging with these topics, you will gain a better understanding of how human oversight and creativity can complement automation, how cross-industry collaboration drives resilience, and how leadership and upskilling are key to thriving in a data-driven world.

In what ways do human intelligence and creativity enhance AI-driven automation in supply chain decision-making, especially in areas requiring problem-solving and innovation, and why is human oversight essential for managing complex, dynamic logistics scenarios that require ethical judgment, adaptability, and crisis intervention?

What is the role of augmented intelligence in a highly automated supply chain, and how does it leverage AI to assist humans in making more informed decisions, improving operational efficiency, and enhancing overall supply chain performance without replacing human judgment and strategic insight?

How can cross-industry collaboration contribute to greater visibility, resilience, and innovation within supply chains, particularly in sectors like healthcare, logistics, and manufacturing, and what collaborative technologies, such as shared data platforms and joint innovation hubs, drive these advancements?

How does blockchain technology facilitate secure, transparent data sharing and collaboration across industries in digital supply chain ecosystems, and what specific use cases demonstrate its ability to enhance trust, streamline processes, and improve accountability in multi-stakeholder environments?

What are the primary challenges in creating a collaborative supply chain ecosystem, including data interoperability, trust, and resource sharing, and how can industries overcome these barriers through governance frameworks, technology adoption, and shared incentives to build stronger, more resilient partnerships?

How can businesses develop effective upskilling and reskilling programs to prepare their workforce for managing AI-powered and digitally transformed supply chains, and what are the most critical skills, such as data literacy, AI system management, and digital problem-solving, that will be in high demand in this transformation?

What role do AI-driven learning platforms play in customizing and personalizing training programs for employees in logistics and supply chain management, and how can these platforms continuously adapt to individual learning paths and evolving industry needs to ensure workforce readiness?

How can virtual and augmented reality (VR/AR) technologies be used to create immersive, hands-on training environments for workers in AI-driven supply chains, particularly for mastering complex tasks such as operating autonomous machinery, managing smart warehouses, or handling AI-integrated logistics systems?

What leadership qualities are crucial for managing data-driven supply chains, and how can leaders balance the integration of technology with human capital by fostering a culture of adaptability, continuous learning, and innovation while making strategic, data-informed decisions?

How can supply chain leaders effectively utilize AI-driven decision-support systems to process vast amounts of real-time data, forecast trends, and make agile, informed decisions in rapidly changing environments, while ensuring alignment with long-term strategic goals and human oversight?

How do human-in-the-loop (HITL) systems improve the effectiveness of supply chain operations by allowing human intervention in critical automated processes, and what are the key scenarios where human judgment is necessary to resolve exceptions, handle anomalies, or ensure ethical outcomes in AI systems?

What are the best practices for fostering a culture of collaboration and innovation within organizations transitioning to digital and AI-powered supply chains, and how can companies encourage cross-functional teams to share knowledge, align goals, and drive innovation across the supply chain?

How can AI and real-time data analytics facilitate more effective cross-functional collaboration between supply chain teams and departments like sales, marketing, and procurement, and what technologies or platforms can be used to enable seamless communication, resource allocation, and decision-making?

How can businesses measure the success and ROI of their cross-industry partnerships in digital supply chain ecosystems, and what key performance indicators (KPIs), such as operational efficiency, risk mitigation, and innovation speed, should be tracked to assess the value of these collaborations?

What are the biggest challenges businesses face in aligning workforce training with the rapid adoption of AI and automation in supply chains, and how can they design training programs that ensure the workforce stays agile, adaptable, and capable of leveraging these new technologies effectively?

How can supply chain leaders create an environment that encourages continuous learning, innovation, and experimentation in a workforce adapting to AI and automation, and what strategies can they use to ensure that employees feel empowered and motivated to embrace technological changes?

How do collaborative leadership platforms enable supply chain leaders to integrate data-driven insights into decision-making processes while maintaining a human-centered approach, and what role do these platforms play in fostering cross-departmental collaboration and strategic alignment?

How can cross-industry collaboration between sectors like logistics, manufacturing, and energy reduce the environmental impact of supply chains by sharing green technologies, adopting sustainable practices, and optimizing resource use, and what are the specific collaborative innovations driving sustainability efforts?

What are the key components of an AI-driven upskilling strategy that ensures employees are adequately prepared for the future of digital supply chains, including adaptive learning platforms, real-time feedback, and customized training paths, and how can businesses measure the effectiveness of these programs?

How can organizations foster seamless collaboration between humans and AI systems in supply chains to ensure that ethical decision-making is maintained, particularly in areas like data privacy, labor practices, and sustainability, and what governance frameworks should be put in place to guide this partnership?

As you reflect on these questions, you’ll be inspired to lead the way in leveraging both human and technological strengths to build smarter, more responsive supply chains. Let these prompts spark your curiosity and motivate you to become an expert in the evolving landscape of supply chain management.

Comments