Chapter 5

Sustainable and Green Supply Chains

"Sustainability is no longer about doing less harm. It’s about doing more good and transforming supply chains to be a force for positive impact." — Paul Polman, former CEO of Unilever.

Chapter 5 of Smart Supply Chain delves into the critical elements of building sustainable and green supply chains. It begins by exploring the challenges and opportunities in designing eco-friendly supply chains, followed by an in-depth look at sustainable procurement and ethical sourcing. The chapter also covers advanced digital tools for carbon footprint monitoring, waste reduction through circular supply chain models, and features real-world case studies of companies successfully implementing green supply chain strategies. Each section highlights the importance of reducing environmental impact while maintaining operational efficiency and competitiveness in today’s global market.

5.1. Designing Eco-Friendly Supply Chains

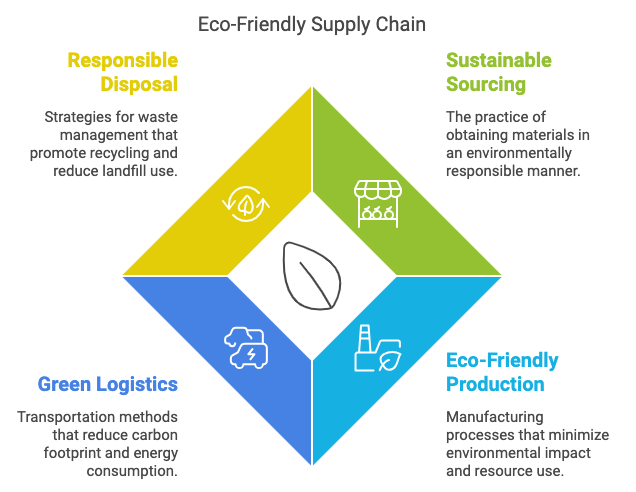

Designing an eco-friendly supply chain involves embedding sustainability into every operational phase, from sourcing and production to logistics and disposal, to minimize environmental impact and promote long-term ecological balance. Recent studies emphasize that such integration is no longer merely a form of corporate social responsibility but a strategic imperative, with companies increasingly recognizing that sustainable supply chains can unlock new markets, bolster brand reputation, and reduce long-term costs (Govindan and Zhang 2024; Deloitte 2023). This shift reflects growing awareness of pressing environmental challenges—climate change, water scarcity, and pollution—that place significant pressure on organizations to adopt more sustainable practices while maintaining competitive advantage (Nikolaou, Evangelinos, and Allan 2021).

However, implementing eco-friendly supply chain strategies requires overcoming notable challenges. One of the most significant issues is managing the trade-off between sustainability and cost-efficiency. Integrating renewable energy systems, employing biodegradable materials, and adopting circular economy principles often involve higher initial capital expenditure, potentially deterring firms focused on short-term profitability (Swanson and Singh 2021). Nonetheless, recent consulting reports suggest that these expenses can be offset over time through energy savings, optimized resource usage, and improved customer loyalty (PwC 2022). Another complexity arises from operating within global supply networks that cross multiple regulatory jurisdictions. Firms must ensure coherence in their environmental standards across various regions, each possessing distinct legal frameworks and infrastructural constraints (Lee et al. 2023). Achieving consistent eco-friendly practices along multi-tiered supply chains is an ongoing concern, highlighting the need for rigorous supplier assessments and capacity-building efforts.

Figure 1: Key Components of Eco-Friendly Supply Chain

From an academic viewpoint, eco-friendly supply chain design aligns with broader paradigms of sustainable development and environmental economics, emphasizing systems resilient enough to meet current needs without compromising future generations (Tachizawa and Wong 2021). In emerging economies, research suggests a unique opportunity for “sustainability leapfrogging,” where newer infrastructure can be built around sustainable energy and logistics systems from the outset, bypassing some of the environmentally detrimental processes experienced by industrialized nations (Chen et al. 2022). Government incentives and public-private partnerships in these regions can further motivate organizations to adopt eco-friendly infrastructure, cultivating growth that is both profitable and ecologically sound (KPMG 2023).

Leading global corporations illustrate the viability of balancing profitability with sustainability. Unilever has made strides through its “Sustainable Living Plan,” which focuses on sourcing materials like palm oil from certified sustainable plantations and incorporating renewable energy in production and logistics (Unilever 2021). Academic evaluations of Unilever’s sustainability initiatives highlight reduced carbon emissions, lower operating costs due to energy efficiencies, and stronger consumer trust (Govindan et al. 2023). Similarly, Nike’s “Move to Zero” campaign underscores a holistic approach to reducing waste and emissions, including utilizing recycled materials in product design and optimizing shipping routes to cut fuel consumption (Nike 2022). These case studies demonstrate how corporates can achieve sustainability targets without sacrificing operational performance.

Regulatory forces and consumer behavior heavily influence the adoption of eco-friendly supply chain designs. Heightened environmental regulations, such as the European Union’s Green Deal, create stringent requirements for emissions reduction, sustainable materials usage, and waste management, pushing companies to comply or risk financial and reputational repercussions (European Commission 2020). Meanwhile, consumer sentiment also drives sustainability efforts, with a rising demographic of environmentally conscious buyers willing to pay premiums for green products or boycott brands that exhibit irresponsible practices (EY 2024). Even in markets with nascent regulatory structures, forward-thinking companies acknowledge that eco-friendly supply chains can generate goodwill, market differentiation, and enhanced long-term profitability (PwC 2022).

To navigate such complexities, organizations are increasingly turning to advanced modeling tools and data analytics to measure, simulate, and optimize the ecological footprint of supply chains. Emerging research points to the effectiveness of digital twin technologies, which offer real-time modeling of supply chain operations to identify bottlenecks, forecast emissions, and simulate the impact of strategic changes under various scenarios (Lee et al. 2023). By harnessing big data and machine learning, firms can evaluate how shifting warehouse locations, altering transportation modes, or redesigning production processes could reduce carbon footprints while sustaining productivity (Choi and Cheng 2023).

Additionally, the adoption of sustainable materials and green logistics practices remains integral to eco-friendly supply chain management. Biodegradable, recyclable, or reusable materials not only reduce dependency on virgin resources but also diminish end-of-life waste (Nikolaou, Evangelinos, and Allan 2021). The electronics and consumer goods industries, for instance, have witnessed significant improvements by using recycled cardboard or bio-based plastics in packaging, evidencing a measurable reduction in landfill usage (Govindan and Zhang 2024). Parallel to material choices, green logistics—such as optimizing transport routes, embracing low-emission vehicles, and participating in carbon offsetting initiatives—enables companies to strategically decrease emissions without compromising operational speed (EY 2024). These practices collectively reinforce the notion that sustainable supply chain operations are both attainable and beneficial, particularly as international trade agreements increasingly prioritize environmental standards (Deloitte 2023).

In conclusion, the global momentum toward eco-friendly supply chain designs underscores their necessity in safeguarding both business viability and the planet’s future. The integration of innovative technologies, sustainable materials, and green logistics empowers firms to reconcile cost concerns with ecological imperatives. Enterprises in emerging economies stand to benefit from designing sustainable infrastructure from the ground up, while established multinationals can leverage their scale and influence to advance responsible sourcing and circular economy approaches. By adopting these strategies, organizations can meet regulatory expectations, attract environmentally conscious consumers, and build resilient, future-ready supply chains that harmonize economic growth with environmental stewardship.

5.2. Sustainable Procurement

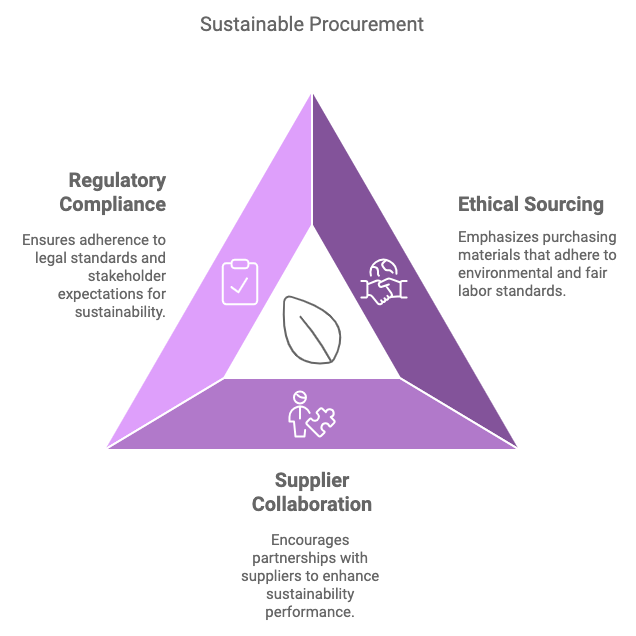

Sustainable procurement refers to the practice of sourcing goods and services in a manner that balances quality, cost-effectiveness, and ethical considerations, ultimately aligning procurement activities with broader environmental and social responsibility goals. Recent studies underscore that sustainable procurement has transcended its status as a voluntary initiative, transforming instead into a critical strategic component for firms seeking both regulatory compliance and market competitiveness (Carter and Rogers 2022). With the intensifying spotlight on climate change, human rights, and social equity, stakeholders—ranging from investors to consumers—demand visibility into how organizations manage their supplier networks. In this context, sustainable procurement has become essential for meeting not only legal obligations but also the elevated expectations of conscientious consumers and business partners (EY 2023; Deloitte 2022).

Figure 2: Key aspects of sustainable procurement.

Ensuring compliance with sustainability standards across a global, multi-tier supplier base remains challenging. Global supply chains often traverse regions with uneven enforcement of labor and environmental regulations, adding complexity to the task of verifying suppliers’ adherence to sustainability requirements (van Hoek, Godsell, and Harrison 2021). While large corporations may have the resources to conduct detailed supplier audits and implement robust sustainability programs, smaller suppliers often lack the infrastructure or capital to meet stringent standards. This dynamic can create friction and potential disruptions if suppliers feel overburdened or inadequately supported. Overcoming these hurdles necessitates the development of strong, trust-based partnerships, supported by consistent communication, well-structured training initiatives, and transparent data sharing (Govindan and Zhang 2024; PwC 2024).

From an academic standpoint, sustainable procurement exemplifies the confluence of environmental economics, corporate social responsibility (CSR), and strategic supply chain management. In CSR theory, ethical sourcing and supplier collaboration are integral elements that emphasize a corporation’s duty to generate value ethically across its value chain (Marques, Ramos, and Teixeira 2023). Meanwhile, partnership theories in supply chain research stress the significance of long-term relationships, shared objectives, and mutual trust among supply chain members (Tachizawa and Wong 2021). For companies in emerging markets, adopting sustainable procurement policies can serve as a gateway to global supply networks, since international buyers increasingly prefer suppliers that can demonstrate responsible sourcing and operational transparency (KPMG 2023).

Real-world examples underscore the practical benefits of sustainable procurement. IKEA’s “IWAY” standard sets rigorous benchmarks for environmental protection, fair labor practices, and efficient resource usage. IKEA actively supports its suppliers by offering training and resources that facilitate transitions to renewable energy or the use of eco-certified raw materials like FSC-certified wood (IKEA 2021). In parallel, Patagonia focuses on upholding high labor standards and using sustainable inputs, such as organic cotton and recycled polyester, to reduce the ecological footprint of its products. Patagonia’s involvement in the Fair Trade program and reliance on certification protocols like Bluesign reflect its commitment to verifying the sustainable and ethical credentials of its global supply base (Patagonia 2022). Both examples highlight how consistent engagement, well-defined procurement criteria, and transparent accountability mechanisms can align procurement activities with broader sustainability objectives.

Supplier scorecards and certification frameworks have emerged as vital instruments for benchmarking and improving supplier sustainability. By quantitatively assessing environmental performance (e.g., carbon footprint, water usage) and social aspects (e.g., labor conditions, community impact), supplier scorecards prompt continuous improvements and encourage peer-to-peer learning across the supply base (Wu and Tseng 2022). Certifications like B Corp or Fair Trade likewise provide verifiable proof of suppliers’ adherence to globally recognized standards, offering buyers an additional layer of assurance (Deloitte 2022). In emerging economies, supplier certification can prove especially beneficial, as it confers credibility and positions local firms competitively in the global marketplace (KPMG 2023).

Technological innovations, especially artificial intelligence (AI) and blockchain, are reshaping the sustainable procurement landscape. AI-driven procurement platforms can aggregate large volumes of supplier data from diverse sources—ranging from compliance audits to social media—and apply machine learning algorithms to spot potential risks or non-compliance in near-real-time (Lee et al. 2023). This level of automation and rapid analysis enables procurement teams to pinpoint issues early, implement corrective measures, and reward suppliers that show consistent improvements in sustainability metrics (PwC 2024). Blockchain technology further strengthens transparency by providing a decentralized and tamper-proof ledger of transactions, thus allowing firms to trace the journey of raw materials and verify ethical compliance at each stage (Choi and Cheng 2023). Whether it is ensuring that cotton is organically farmed or that minerals are conflict-free, blockchain offers a mechanism to securely document evidence of compliance, thereby bolstering stakeholder confidence.

Notably, these technologies also open pathways for smaller suppliers to enhance their visibility and credibility. Through AI platforms, suppliers can share performance data that might otherwise remain inaccessible, building trust with global buyers. Blockchain’s traceability, meanwhile, can help suppliers in regions with less robust regulatory systems demonstrate adherence to international standards, thereby unlocking new market opportunities (EY 2023). As both AI and blockchain mature, they are likely to play an increasingly integral role in enabling data-driven decision-making, continuous supplier engagement, and dynamic risk management—all of which reinforce sustainable procurement objectives.

In conclusion, sustainable procurement has evolved into a cornerstone strategy for corporations aiming to balance cost-effectiveness, risk mitigation, and ethical mandates in supply chain management. By emphasizing ethical sourcing, establishing collaborative relationships, and leveraging emerging digital tools, firms can create procurement systems that are transparent, adaptable, and aligned with the demands of environmentally and socially conscious stakeholders. As consumer and regulatory pressures intensify worldwide, sustainable procurement offers a proactive avenue for companies to not only safeguard their reputations but also contribute constructively to global sustainability targets. With advancements in AI, blockchain, and enhanced certification protocols, the concept of procurement as a value-adding, sustainability-driving force is poised to become even more central in shaping the future of global supply chains.

5.3. Carbon Footprint Monitoring

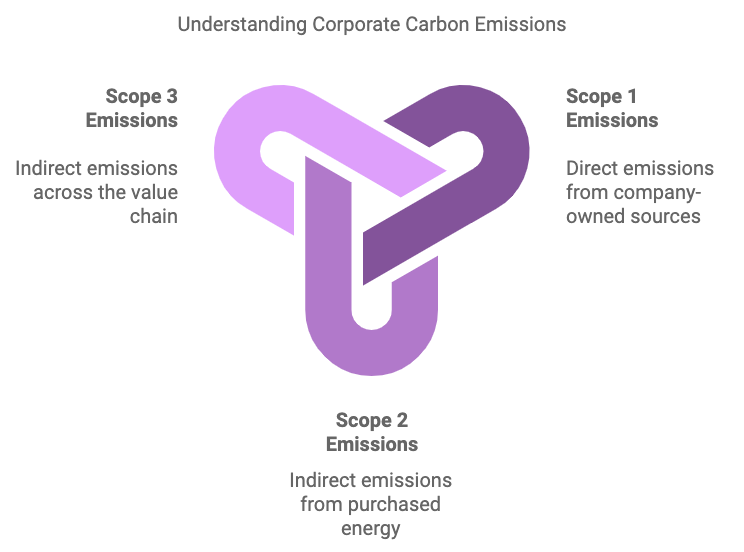

Carbon footprint monitoring has become a cornerstone of modern supply chain management, reflecting the heightened urgency to reduce greenhouse gas (GHG) emissions and comply with evolving sustainability standards. Recent studies show that accurate carbon accounting not only helps companies fulfill regulatory obligations but can also uncover cost efficiencies and enhance brand reputation (Roehrich, Grosvold, and Hoejmose 2022; Deloitte 2024). By quantifying total GHG emissions from production, logistics, energy consumption, and even end-user product disposal, organizations can pinpoint areas for reduction, measure progress over time, and bolster transparency in a market increasingly attentive to environmental performance (Wu et al. 2023).

A comprehensive approach to carbon footprint monitoring often aligns with the three scope framework defined by the Greenhouse Gas Protocol—Scope 1 (direct emissions), Scope 2 (indirect emissions from purchased energy), and Scope 3 (all other indirect emissions). Scope 3, frequently the largest share of a company’s carbon footprint, extends across the entire value chain, encompassing supplier activities, outsourced transport, and product end-of-life. Monitoring Scope 3 can pose significant data-collection challenges, particularly within global networks where variable regulatory regimes, limited technological capabilities, or inconsistent reporting standards impede accurate measurements (KPMG 2023). However, an increasing array of digital tools and collaborative platforms has emerged to address these hurdles, enabling firms to gather granular data from suppliers, partners, and distribution networks (Govindan and Zhang 2024).

Figure 3: Overview of Corporate Carbon Emissions

From an academic perspective, carbon footprint monitoring draws on environmental science and sustainability metrics, providing a tangible basis for identifying carbon hotspots and implementing targeted decarbonization strategies (Lee et al. 2023). The relevance is especially pronounced in emerging economies that experience rapid industrial expansion. By integrating technological solutions for emissions tracking—such as real-time data capture and big data analytics—companies in these regions can minimize their environmental impact while forging stronger ties with global partners (Sarkis, Zhu, and Lai 2022). Through proactive carbon monitoring, emerging-market firms can also align more readily with international standards, facilitating trade relationships that increasingly hinge on demonstrable environmental performance (PwC 2025).

Corporate pioneers like Apple and Microsoft illustrate the pivotal role of transparent carbon accounting. Apple leverages cloud-based platforms to consolidate emissions data across its supply chain and has introduced requirements for suppliers to transition toward renewable energy sources (Apple 2021). By systematically tracking Scope 3 emissions, Apple incentivizes suppliers to adopt low-carbon practices, thereby embedding sustainability throughout its operational ecosystem. Microsoft similarly employs artificial intelligence (AI) and advanced analytics tools to gather real-time insights into energy consumption, transportation emissions, and supply chain processes (Microsoft 2022). These insights help the company not only reduce its own footprint but also guide suppliers and customers in lowering their carbon emissions. Both companies’ commitments to public reporting underscore a broader industry trend, wherein emissions transparency is increasingly viewed as an indicator of corporate accountability and strategic foresight (EY 2023).

Evolving government policies and international agreements further compel companies to adopt robust carbon monitoring systems. The European Union’s Carbon Border Adjustment Mechanism (CBAM) exemplifies legislation that puts a price on carbon-intensive imports, pushing global exporters to enhance emissions tracking and invest in cleaner technologies (European Commission 2021). Similar regulatory measures in other jurisdictions, coupled with investor-driven environmental, social, and governance (ESG) standards, highlight that inadequate carbon reporting can result in reputational damage, financial penalties, or restricted market access (Deloitte 2024). Consequently, implementing comprehensive carbon footprint monitoring is no longer a choice but an imperative to remain competitive and compliant in an era of escalating environmental scrutiny.

Advancements in AI and the Internet of Things (IoT) have accelerated the adoption of real-time carbon tracking systems. AI-powered platforms leverage machine learning algorithms to fuse data from diverse sources—energy usage logs, transportation records, and supplier declarations—quickly identifying emission hotspots and suggesting targeted interventions (Choi and Cheng 2023). The addition of IoT sensors in facilities and vehicles provides granular metrics on energy consumption, machinery efficiency, and route optimization, offering unprecedented visibility into the carbon footprint across the value chain (Nikolaou et al. 2022). According to a recent report by KPMG (2023), companies employing AI-driven and IoT-enabled carbon monitoring solutions have seen an average 15% reduction in emissions over three years, underscoring the tangible environmental and operational benefits of digital innovation.

In emerging markets, these technological breakthroughs can be transformational, equipping local suppliers with tools to record and verify emissions data more accurately. Collaboration with multinational corporations often triggers technology transfers and knowledge sharing that uplift the entire supply chain’s environmental performance (Sarkis et al. 2022). Companies demonstrating strong carbon reporting capabilities may also leverage green financing and tax incentives designed to reward low-carbon business practices (PwC 2025). As a result, carbon monitoring can serve as both a mechanism for reducing emissions and a driver of economic competitiveness in rapidly industrializing regions.

In sum, the convergence of AI, IoT, and advanced analytics fosters a new era of carbon footprint monitoring, enabling unprecedented levels of transparency, granularity, and actionable insights. By systematically tracking Scope 1, 2, and 3 emissions, companies can respond proactively to regulatory changes, investor demands, and consumer expectations for environmental responsibility. Moreover, the integration of these data-driven strategies is particularly salient for emerging markets striving to harmonize economic development with ecological stewardship. As stakeholder interest in carbon accountability intensifies worldwide, robust emissions monitoring stands as a critical pillar of modern, sustainable supply chain management—ensuring that organizations both mitigate their climate impacts and unlock efficiencies that drive competitive advantage.

5.4. Waste Reduction and Recycling

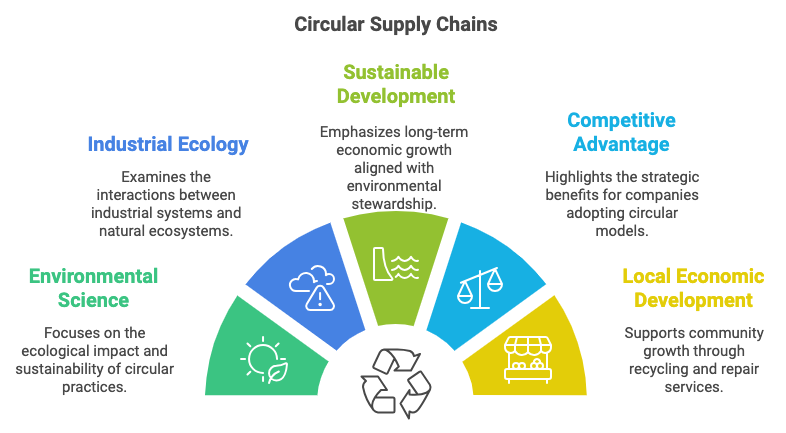

The shift from linear to circular supply chains underscores a transformative approach to resource management by emphasizing waste reduction, material reuse, and product recycling. Traditional linear supply chains often follow the “take-make-dispose” model, which depletes natural resources and contributes to environmental degradation (Geissdoerfer et al. 2021). In contrast, circular supply chains strive to retain the value of materials throughout their lifecycle by facilitating closed-loop processes, reintroducing used products and components into new production cycles. This model aligns with the principles of the circular economy, wherein resources are used more efficiently, products are designed for longevity, and waste is minimized (KPMG 2024).

From an academic standpoint, circular supply chains intersect with disciplines such as industrial ecology, environmental science, and sustainable development. One core idea is that “cradle-to-cradle” design can substantially reduce the ecological footprint by allowing products to be easily disassembled, repaired, or recycled (Govindan et al. 2022). In emerging markets, the adoption of circular principles offers dual benefits. On one hand, businesses can reduce their reliance on virgin materials, mitigating supply chain risks and resource constraints. On the other, they can create local industries around recycling, remanufacturing, and repair services, thereby fostering job creation and sustainable economic growth (Deloitte 2025).

Figure 4: High-Level Overview of Circular Supply Chains

A high-profile example of circular supply chain application can be found in the electronics sector. Dell’s take-back program illustrates how returned devices are disassembled, reconditioned, and reintegrated into manufacturing processes (Dell 2022). By converting end-of-life products into valuable resources, Dell not only curbs waste but also curtails its need for raw materials, thus decreasing costs and environmental impact (PwC 2023). Similarly, HP’s Planet Partners initiative advances remanufacturing and recycling efforts by collecting printers and ink cartridges, refurbishing viable parts, and recycling what remains (HP 2021). Through this closed-loop system, HP extends product lifespans, reduces production costs, and bolsters its reputation as a leader in sustainability (EY 2023).

The fashion industry has also begun embracing circular models, with H&M pioneering garment collection programs that facilitate resale or recycling of returned items. Wearable garments are channeled toward secondhand markets, whereas damaged textiles are recycled into new fabrics, such as those used in the “Conscious Collection” (Deloitte 2025). These efforts not only reduce textile waste but also resonate with consumers who prioritize environmental responsibility. In regions where waste management infrastructures are underdeveloped, circular supply chains can be instrumental in alleviating landfill pressures and stimulating local circular economies (Geissdoerfer et al. 2021).

Recent advancements in AI and the Internet of Things (IoT) provide robust mechanisms for implementing circular principles. AI-powered analytics platforms can scrutinize product usage data, predict maintenance needs, and optimize material flows, thereby extending component lifecycles (Choi and Cheng 2023). For example, IoT-enabled sensors embedded in machinery can continuously relay performance data, allowing firms to schedule refurbishments before failures occur (Govindan et al. 2022). This predictive approach, in turn, supports the circular principle of longevity, reducing wasteful practices and preventing premature product disposal (KPMG 2024). Moreover, digital platforms that match surplus material streams with manufacturers in need of recycled inputs have become increasingly prevalent, creating synergistic relationships that further reduce overall resource consumption (PwC 2023).

These innovations are particularly relevant in emerging markets, where inadequate recycling infrastructure and limited access to raw materials can hamper industrial development. By leveraging digital tools and collaborating with multinational partners, local firms can embed circular operations and gain credibility for meeting international sustainability standards (EY 2023). The economic logic is compelling: the upfront investment in AI, IoT, or reverse logistics technology can be offset by reductions in material costs, landfill fees, and regulatory compliance expenses (Deloitte 2025).

Ultimately, integrating circular economy principles into supply chains is no longer just an environmental objective; it is emerging as a competitive strategy. As governments impose stricter waste regulations and consumers favor eco-conscious brands, organizations that proactively adopt circular models can secure market advantages and foster long-term resilience (HP 2021; Dell 2022). By transforming waste streams into resources, businesses align profit motives with environmental stewardship. These practices will likely gain momentum as digital tools continue to evolve, making it increasingly feasible to track, reclaim, and repurpose materials at scale. In essence, circular supply chains epitomize the future of resource management, pairing economic viability with ecological responsibility, and setting a clear pathway toward a regenerative, low-waste global economy.

5.5. Case Studies on Green Supply Chain Strategies

Green supply chain strategies integrate environmental sustainability into every facet of supply chain operations, encompassing production, logistics, waste management, and recycling. Recent studies underscore that these initiatives can reduce operational costs, strengthen brand reputation, and enhance compliance with increasingly stringent environmental regulations (Roehrich, Grosvold, and Hoejmose 2022; Deloitte 2023). By optimizing transportation routes, adopting renewable energy sources, minimizing waste, and promoting circular economy principles, companies not only mitigate their ecological footprint but also gain resilience against resource volatility and future market shifts (Nikolaou et al. 2021). From an academic standpoint, such green strategies intersect with environmental economics and systems thinking, emphasizing a holistic approach that balances ecological benefits with business performance (Govindan and Zhang 2024).

In emerging economies, green supply chain adoption presents a dual opportunity to address pressing local environmental challenges and meet global sustainability benchmarks (PwC 2022). Rapid industrialization in these markets often compounds issues like air pollution, resource depletion, and inadequate waste management. By embracing sustainable practices—such as carbon footprint reduction, product recycling, and responsible sourcing—companies can attract international investors, boost export competitiveness, and foster job creation in green industries (KPMG 2024). This alignment with corporate social responsibility (CSR) imperatives supports long-term economic development while contributing to the global agenda on climate change mitigation.

Two prominent examples illustrate the tangible outcomes of green supply chain initiatives. Tesla, renowned for its electric vehicles and battery innovations, integrates renewable energy in its Gigafactories and invests heavily in closed-loop battery recycling (Tesla 2023). By systematically reclaiming valuable minerals like lithium and cobalt from end-of-life batteries, Tesla reduces raw material dependency and lowers waste generation (Choi and Cheng 2023). This closed-loop approach not only advances the company’s sustainability goals but also translates into cost savings over the product lifecycle. Moreover, Tesla’s use of solar power in its manufacturing processes further demonstrates how renewable energy integration can significantly shrink carbon footprints and operational expenses (EY 2024).

Walmart provides another compelling case study of a large-scale green supply chain transformation. Through Project Gigaton, Walmart aims to cut one billion metric tons of greenhouse gases from its supply chain by 2030, collaborating with suppliers to implement energy efficiency measures, reduce emissions, and adopt sustainable sourcing methods (Walmart 2021). This collaboration extends to optimizing transportation networks, deploying more efficient refrigeration systems, and transitioning toward electric vehicle fleets. Sustainability reporting, guided by frameworks like the Global Reporting Initiative (GRI) and Science-Based Targets (SBT), allows Walmart to track progress rigorously and maintain transparency (Govindan and Zhang 2024). By engaging suppliers in these initiatives, the retailer not only mitigates environmental risks but also secures long-term supply chain resilience and consumer trust (Deloitte 2023).

Measuring the success of green supply chain strategies increasingly involves adherence to global standards. ISO 14001 certification, for instance, compels companies to systematize their environmental management processes and continually improve resource efficiency (Roehrich, Grosvold, and Hoejmose 2022). Science-Based Targets (SBTs) ensure that corporate emissions-reduction commitments align with the Paris Agreement’s objective of limiting global temperature rise to well below 2°C (Nikolaou et al. 2021). These frameworks are enhanced by digital tools, such as blockchain and AI, which offer real-time supply chain visibility and predictive analytics. Blockchain provides an immutable record of transactions and environmental data, helping firms verify sustainable sourcing and carbon footprints across multiple tiers (KPMG 2024). Meanwhile, AI-driven applications optimize resource usage, model potential environmental impacts, and deliver actionable insights for continuous improvement (Choi and Cheng 2023).

Renewable energy integration and electrified transportation fleets further epitomize the innovation within green supply chains. As solar, wind, and hydroelectric power become more cost-effective, companies increasingly rely on clean energy to run factories, warehouses, and distribution centers (EY 2024). Alongside this transition, electrified transport fleets—ranging from delivery vans to long-haul trucks—significantly reduce fuel-related emissions and help meet urban air quality regulations (PwC 2022). For emerging markets, the adoption of electric vehicles can alleviate pollution in congested city centers and foster local manufacturing of low-emission technologies (KPMG 2024). Consequently, these green investments serve both global sustainability objectives and localized public health goals.

Overall, green supply chain strategies highlight how enterprises can align profitability with environmental stewardship in a market landscape increasingly shaped by climate concerns and resource constraints. By incorporating advanced technologies, adhering to international standards, and collaborating extensively with suppliers and stakeholders, companies create resilient, transparent, and eco-conscious supply chains (Govindan and Zhang 2024). The practices pioneered by Tesla and Walmart exemplify how tangible sustainability gains can be achieved through targeted emissions reduction, circular material management, and robust reporting. As global attention intensifies around sustainability, the momentum toward green supply chains is poised to reshape how companies create value, safeguard the planet, and meet the evolving expectations of customers, investors, and regulators.

5.6. Conclusion and Further Learning

In conclusion, creating sustainable and green supply chains is essential for businesses to remain competitive in an increasingly eco-conscious world. By embracing circular economy principles, ethical sourcing, and advanced carbon monitoring technologies, companies can significantly reduce their environmental impact while improving operational efficiency. As more companies adopt these strategies, sustainable supply chains will not only benefit the planet but also foster innovation, build consumer trust, and enhance long-term profitability.

Exploring the following prompts will give you valuable insights into the evolving landscape of sustainable and green supply chains. By engaging deeply with these topics, you will not only gain a better understanding of how to reduce environmental impact but also discover how sustainability can drive innovation and long-term business success.

What are the primary challenges companies face when designing eco-friendly supply chains, such as balancing cost, scalability, and regulatory requirements, and how can these challenges be addressed through the use of innovative technologies like AI, blockchain, and IoT, along with strategic partnerships and process redesign?

How can businesses effectively balance cost efficiency with environmental sustainability in supply chain design, particularly when incorporating renewable energy sources, sustainable materials, and eco-friendly logistics, while ensuring long-term profitability and compliance with global sustainability standards?

What are the most advanced strategies for reducing carbon emissions across global supply chains, particularly in high-emission sectors like transportation and logistics, and how can technologies such as electric vehicles, AI-driven route optimization, and renewable energy adoption play a critical role in decarbonizing supply chain operations?

How can AI-driven procurement platforms leverage real-time data analytics to ensure ethical sourcing, enhance supplier collaboration, and monitor sustainability metrics, and what role does predictive modeling play in identifying and mitigating risks in global supplier networks?

What specific advantages does blockchain technology offer for improving transparency, traceability, and accountability in sustainable procurement, particularly in tracking the origin, environmental impact, and ethical sourcing of materials, and how can it integrate with AI to automate compliance with sustainability standards?

How do advanced digital tools for carbon footprint monitoring, such as AI-powered platforms and IoT-based sensors, function in gathering real-time emissions data across supply chain operations, and what are the best practices for integrating these tools to ensure accurate, transparent, and actionable carbon tracking?

What are the most effective practices for reducing Scope 3 emissions in supply chains—emissions generated by suppliers, transportation, and product use—and how can companies collaborate with suppliers through technology-driven solutions like blockchain and digital platforms to achieve verifiable emission reductions?

What are the key principles of the circular economy, such as resource efficiency, waste minimization, and product lifecycle extension, and how can they be practically applied to redesign global supply chains to prioritize sustainability through closed-loop systems, reverse logistics, and sustainable product design?

How can AI and IoT technologies be used together to optimize waste reduction, recycling, and resource efficiency within circular supply chain models, and what are the critical technological and operational enablers for scaling these efforts across industries?

How do take-back programs and reverse logistics contribute to building a more sustainable supply chain by extending product lifecycles, enabling recycling, and reducing waste, and what are the key operational, regulatory, and logistical challenges companies face when implementing these systems on a global scale?

How can companies accurately measure the ROI of implementing green supply chain strategies, including investments in renewable energy, sustainable sourcing, and carbon reduction technologies, and what specific metrics—such as carbon footprint, energy efficiency, and long-term cost savings—should be tracked to evaluate success?

How can businesses work collaboratively with suppliers to ensure compliance with sustainability certifications like Fair Trade and B Corp, and what role do digital platforms, supplier scorecards, and real-time monitoring systems play in ensuring alignment with environmental, social, and governance (ESG) goals?

What regulatory frameworks, such as the European Green Deal and U.S. Clean Energy Act, and global standards, like ISO 14001 and the Science-Based Targets initiative, influence the adoption of sustainable supply chain practices, and how can companies proactively ensure compliance while staying ahead of future regulations?

How can AI-powered digital platforms help companies align their sustainability strategies with consumer demand for eco-friendly products by providing real-time insights into environmental impact, supply chain efficiency, and product sourcing, and how do these platforms enable businesses to build stronger connections with sustainability-conscious consumers?

What are the emerging trends in sustainable packaging, such as biodegradable materials, reusable containers, and zero-waste design, and how do these innovations contribute to reducing environmental impact throughout the supply chain while meeting regulatory requirements and consumer expectations for eco-friendly products?

How can businesses integrate renewable energy into their supply chain operations, particularly in manufacturing and logistics, and what are the most effective ways to transition from traditional energy sources to solar, wind, and electrified transportation while ensuring cost-efficiency and minimal operational disruption?

What role do consumers play in driving demand for greener supply chains, and how can companies respond effectively by incorporating sustainability into their brand messaging, product design, and supply chain transparency to build trust and meet the growing demand for environmentally responsible products?

What key lessons can be learned from companies that have successfully implemented circular supply chain models, such as Dell’s recycling program and HP’s product take-back initiatives, and how can these models be replicated and scaled to other industries seeking to achieve sustainability and reduce waste?

How can AI-powered predictive analytics help companies forecast, measure, and reduce their carbon footprint across the entire supply chain, from raw material sourcing to product distribution, and what are the most effective tools and methodologies for achieving measurable carbon reduction targets?

What are the long-term competitive advantages of adopting sustainable supply chain practices, including enhanced brand reputation, operational efficiency, regulatory compliance, and consumer loyalty, and how can companies leverage these benefits to differentiate themselves in the global marketplace and drive market growth?

Each question encourages you to think critically about how emerging technologies, ethical practices, and strategic collaborations can create more resilient and eco-friendly supply chains. Dive into these prompts with curiosity, and let them guide you toward becoming a leader in the sustainable transformation of supply chains.

Comments