Chapter 4

Innovation in Supply Chain Operations

"The future of supply chain operations lies in automation, intelligence, and sustainability. We are building smarter systems that respond to real-time data, mitigate risks, and enable a truly circular economy." — Leif Johansson, Chairman of AstraZeneca and Ericsson.

Chapter 4 explores cutting-edge innovations in supply chain operations, focusing on how autonomous technologies, AI, and sustainability initiatives are transforming key aspects of the supply chain. It covers the role of smart warehousing with autonomous robots and AI-driven inventory management, the use of AI in procurement and sourcing, and the adoption of drones and autonomous vehicles for optimizing last-mile delivery. Additionally, the chapter delves into the integration of circular economy principles to enhance sustainability and the use of AI to build resilient supply chains that can mitigate risks and disruptions. Together, these innovations offer solutions to enhance operational efficiency, sustainability, and resilience in the modern supply chain.

4.1. Smart Warehousing

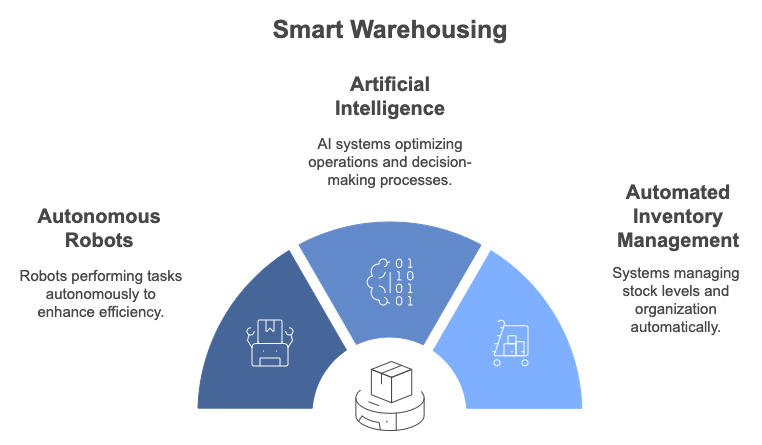

Smart warehousing has revolutionized logistics operations by fusing robotics, artificial intelligence (AI), and advanced inventory management systems into a cohesive ecosystem (Singh and Park 2022). This convergence addresses the complexities of contemporary e-commerce, where speed, accuracy, and scalability are essential for meeting fluctuating consumer demands. According to a 2023 KPMG report on digital supply chain transformations, over 60% of leading global retailers are expanding investments in warehouse automation, highlighting its growing importance for competitiveness (KPMG 2023). By automating tasks such as picking, packing, sorting, and inventory management, smart warehouses not only reduce labor costs but also enhance precision, throughput, and safety, enabling organizations to adapt rapidly to market changes (Deloitte 2024).

A key driver of smart warehousing is the implementation of Warehouse Management Systems (WMS) that integrate data from diverse sources—such as IoT sensors, robotics, and inventory databases—to optimize space utilization and ensure real-time visibility of stock levels (Joshi et al. 2021). These platforms often employ AI algorithms to predict demand patterns, automatically reorder items, and configure optimal storage layouts. Autonomous mobile robots (AMRs) further bolster efficiency by transporting goods and assisting with replenishment tasks. Equipped with cameras, sensors, and machine learning capabilities, these robots navigate warehouse floors with minimal human intervention, drastically reducing both picking times and the potential for human error (Singh and Park 2022).

Figure 1: Smart Warehousing technologies are powered by robots, AI and automation.

From an academic standpoint, smart warehousing represents a prime example of cyber-physical integration—a core principle of Industry 4.0—where advanced computing and physical automation converge to deliver seamless processes (Hu et al. 2023). The adaptability of these systems makes them suitable for both developed economies with sophisticated infrastructures and emerging markets seeking scalable, cost-effective solutions. Emerging regions, in particular, benefit from smaller-scale robotic platforms and AI-driven tracking systems that can be implemented with relatively modest capital expenditure (KPMG 2023). Such solutions help address labor shortages, improve operational consistency, and facilitate entry into global e-commerce networks.

Amazon: A pioneer in warehouse robotics, Amazon introduced autonomous robots through the acquisition of Kiva Systems. In Amazon’s fulfillment centers, these robots transport goods to human pick stations, significantly reducing travel time and physical strain on workers (Deloitte 2024). This automation enables Amazon to handle millions of orders daily, particularly during peak demand seasons like Black Friday and Cyber Monday, while maintaining high accuracy rates and rapid fulfillment.

Ocado: The British online grocery retailer Ocado employs a highly automated warehousing system featuring thousands of robots operating on a grid-like structure (Hu et al. 2023). These robots collaborate to pick and pack grocery items based on real-time orders. Coupled with AI-driven demand forecasting, Ocado aligns inventory levels with precise consumer needs, thereby minimizing both waste and stockouts. This model demonstrates how integrated robotics and predictive analytics can optimize perishable goods management in high-volume environments (Singh and Park 2022).

AI-powered inventory management systems are increasingly indispensable in both retail and manufacturing sectors (Hu et al. 2023). By analyzing historical sales data, consumer behavior, and seasonal trends, these systems generate accurate demand forecasts, triggering automatic replenishment when stock thresholds are reached. Large-scale retailers benefit from real-time monitoring of inventory flows across multiple distribution centers, reducing overstock scenarios and stockouts (Joshi et al. 2021). Manufacturers, on the other hand, rely on AI to synchronize raw materials with production timelines, ensuring lean operations that align with just-in-time principles. In both contexts, AI-driven inventory models significantly enhance supply chain visibility and responsiveness (KPMG 2023).

Another transformative innovation is the rise of collaborative robots (cobots), designed to work in proximity to human workers (Singh and Park 2022). Cobots are equipped with advanced sensors and safety protocols, enabling them to perform repetitive or physically demanding tasks—such as lifting heavy loads—while human operators focus on more complex responsibilities. This synergy alleviates labor constraints, increases throughput, and reduces occupational hazards (Deloitte 2024). Particularly in facilities where full automation is neither feasible nor cost-effective, cobots offer a middle ground that combines the strengths of automated precision and human adaptability.

Drones and autonomous ground vehicles are increasingly deployed for inventory audits and real-time tracking in expansive warehouses. By scanning barcodes or RFID tags, drones rapidly collect stock-level data while traversing aisles (Joshi et al. 2021). Autonomous vehicles with LiDAR sensors navigate the warehouse floor, moving goods between storage areas, picking stations, and loading docks without human intervention. These technologies reduce manual labor, improve data accuracy, and allow more frequent inventory checks (Hu et al. 2023). In emerging markets, where labor shortages or efficiency gaps may exist, drone-based inventory assessments have proven especially valuable, cutting cycle count times and minimizing disruptions (KPMG 2023).

As robotics, AI, and IoT technologies continue to mature, smart warehousing is poised to become an even more integral part of adaptive, resilient supply chains. The ability to reconfigure storage layouts, reposition robots, and adjust inventory flows in real time allows warehouses to adapt to sudden spikes in demand or disruptions like labor shortages and transportation delays (Deloitte 2024). These attributes are particularly pertinent in a global environment where consumer expectations for rapid delivery continue to escalate. By embracing autonomous robots, AI-driven inventory management, collaborative robotics, and drone-based auditing, organizations can forge hyper-efficient and flexible warehouse operations that form the backbone of modern omnichannel supply networks (Singh and Park 2022).

4.2. Smart Procurement and Sourcing

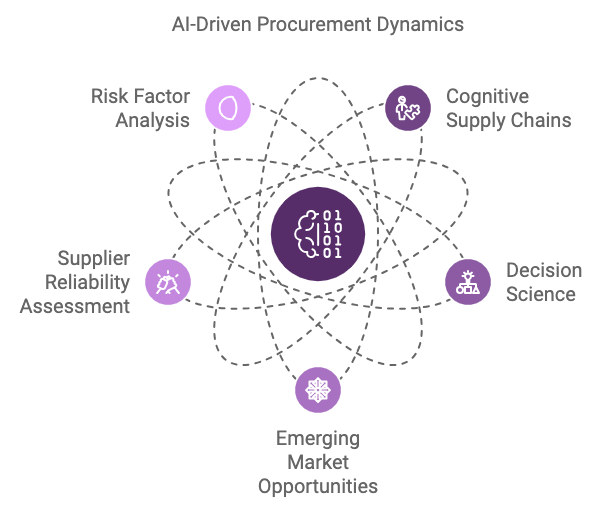

Smart procurement and sourcing, enhanced by artificial intelligence (AI), have become essential for organizations seeking to build agile, resilient, and cost-effective supply chains (Chen et al. 2022). Traditional procurement processes, often reliant on manual data gathering and intuitive decision-making, can no longer keep pace with rapidly evolving global markets and supplier complexities (KPMG 2023). In contrast, AI-driven procurement platforms integrate large-scale data—from supplier performance histories to market signals and geopolitical indicators—to deliver real-time insights, optimize supplier selections, and shape dynamic sourcing strategies. According to a 2024 Deloitte report on cognitive supply chains, over 70% of industry leaders rate AI-enabled procurement as crucial for enhancing cost savings and mitigating supply risks (Deloitte 2024).

Figure 2: Smart Procurement is powered by AI capabilities.

The shift toward AI-enabled procurement underscores a broader trend of cognitive supply chains, where advanced algorithms automate complex tasks like supplier evaluation, contract management, and risk assessments (Johnson et al. 2021). By analyzing historical performance, financial stability, and production capacities, AI systems can rank suppliers based on reliability and alignment with corporate goals. Such capabilities are particularly significant for industries like healthcare and automotive, where disruptions can trigger costly delays or regulatory complications (KPMG 2023). Over time, machine learning models refine their predictive accuracy, allowing procurement teams to respond proactively to shifting market conditions, rather than reacting to sudden changes in demand or supplier performance (Chen et al. 2022).

IBM: IBM employs an AI-driven procurement platform, Watson Supply Chain, which leverages natural language processing (NLP) and predictive analytics to streamline supplier selection (Deloitte 2024). By cross-referencing historical contracts, pricing trends, and supplier performance metrics, the system identifies cost-efficient, reliable partners. IBM’s approach expedites decision-making, trims negotiation times, and reduces reliance on manual checks, resulting in more consistent supplier relationships and lower operational costs (KPMG 2023).

Siemens: At Siemens, AI underpins dynamic sourcing and spend analytics. Real-time market data, procurement benchmarks, and supplier scorecards are combined to guide decision-making on bids and contract terms (Johnson et al. 2021). Algorithms continuously evaluate vendor reliability and cost-effectiveness, prompting Siemens to pivot sourcing strategies when needed. This data-driven method not only shields supply chains from unforeseen disruptions but also reveals areas for cost savings through consolidated supplier portfolios and optimized contract terms (Chen et al. 2022).

Supplier Risk Monitoring: One of AI’s most transformative roles in procurement involves continuous supplier risk assessments. By analyzing real-time data—such as macroeconomic trends, political instability, and sustainability indicators—algorithms can flag vulnerabilities in supplier networks (KPMG 2023). For example, if a key component manufacturer lies in a region experiencing political unrest or severe weather threats, AI-driven systems can recommend alternate suppliers or enhanced buffer stocks to mitigate potential slowdowns (Chen et al. 2022).

Blockchain Synergy: Integrating AI with blockchain further elevates transparency and accountability in procurement (Johnson et al. 2021). A blockchain ledger provides an immutable record of supplier transactions, certifications, and contract terms, while AI continuously validates data accuracy and quality. In regulated sectors—like pharmaceuticals—this synergy assures customers and regulators that each procurement step aligns with compliance standards. Additionally, smart contracts automate milestone-based payments: if a delivery meets predefined criteria, the blockchain triggers payment, verified by AI algorithms scanning performance data (Deloitte 2024). This automation cuts administrative overhead and reduces the risk of disputes.

AI-powered predictive analytics delve into historical records and external factors—ranging from commodity prices to weather forecasts—to anticipate potential disruptions (KPMG 2023). In volatile markets, such as agriculture or electronics manufacturing, procurement teams gain early warnings about supplier shortfalls, currency fluctuations, or logistical bottlenecks (Chen et al. 2022). This foresight allows companies to adjust sourcing strategies preemptively—by diversifying suppliers or recalibrating safety stocks—thereby minimizing the operational impact of disruptions. The approach is especially beneficial in emerging economies, where infrastructure challenges and regulatory changes can heavily influence supplier reliability (Johnson et al. 2021).

The continued advancement of AI, blockchain, and predictive analytics signals a profound evolution in procurement and sourcing (Deloitte 2024). As data volumes expand and algorithms mature, procurement operations will likely adopt more proactive, scenario-based strategies that weigh cost efficiency against sustainability goals, risk tolerance, and supplier diversity (KPMG 2023). Moreover, AI-driven platforms will become more accessible, enabling even small and medium enterprises in emerging markets to leverage robust sourcing analytics and global supplier networks (Chen et al. 2022).

Ultimately, AI-powered procurement transcends traditional cost reduction efforts, driving comprehensive benefits that include elevated supplier relationships, improved compliance, and a heightened capacity to navigate market uncertainties. In an interconnected global economy, these qualities set the stage for sustainable competitive advantages, as companies that master AI-driven procurement can rapidly align resources and partnerships with real-time industry demands (Johnson et al. 2021).

4.3. Intelligent Logistics

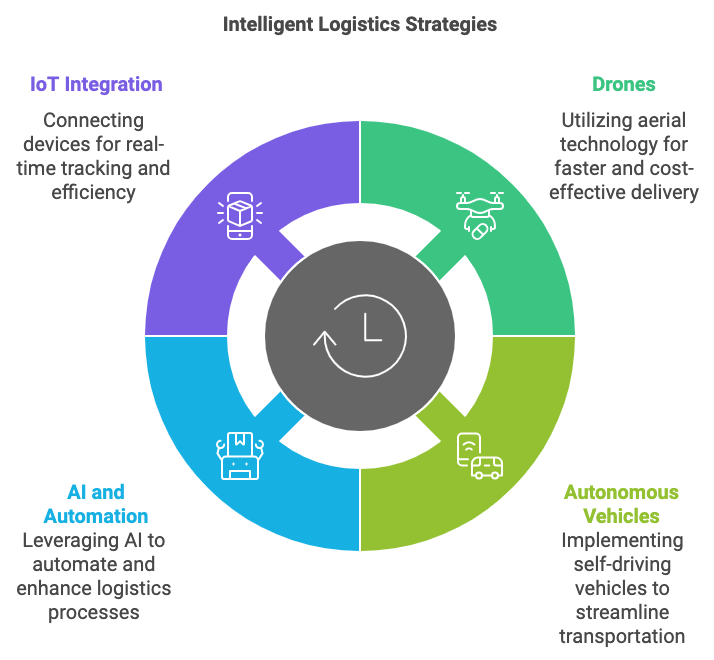

Intelligent logistics encompasses the integration of advanced technologies—including artificial intelligence (AI), automation, and the Internet of Things (IoT)—into logistics operations to improve efficiency, accuracy, and sustainability (Gomes et al. 2022). One of the most pressing challenges within intelligent logistics is last-mile delivery, recognized as both the costliest and most time-sensitive phase of product distribution (PwC 2025). According to a 2023 Deloitte study on supply chain digitization, last-mile costs can account for up to 53% of overall shipping expenses, underscoring the critical role innovation plays in enhancing delivery speed, reducing congestion, and managing fuel consumption (Deloitte 2023). Drones and autonomous vehicles have emerged as transformative solutions to address these challenges, offering more flexible, reliable, and often cost-effective modes of transporting goods to consumers.

Figure 3: Application of Intelligent Logistics

Autonomous ground vehicles (AGVs) and drones are reshaping how parcels reach end customers, especially in densely populated urban centers and remote rural zones (Gomes et al. 2022). Equipped with sensors, cameras, and AI-driven navigation algorithms, these systems determine the safest and most efficient delivery routes in real time. Drones, for instance, can bypass traffic altogether by navigating urban airspace or challenging terrains, significantly reducing travel times (KPMG 2023). Autonomous ground vehicles, meanwhile, excel in areas with well-defined roads and pedestrian paths, minimizing reliance on human drivers and optimizing route efficiency. Both approaches aim to decrease delivery windows, enhance customer satisfaction, and lower operational overhead by automating processes that traditionally depend on labor-intensive activities.

UPS and Flight Forward: UPS has integrated drone technology through its subsidiary, Flight Forward, focusing on healthcare deliveries and remote rural services (PwC 2025). Drones enable the rapid transport of critical items—such as vaccines and medical supplies—across long distances without the constraints of road infrastructure. This approach reduces operational costs, enhances service reliability, and supports essential healthcare missions in challenging environments (KPMG 2023).

Amazon Prime Air: In contrast, Amazon’s Prime Air targets urban and suburban regions, using drones to deliver lightweight packages within 30 minutes or less (Gomes et al. 2022). By leveraging AI to navigate complex cityscapes, Amazon aims to reduce reliance on delivery trucks and elevate consumer convenience. This initiative aligns with the broader company goal of automating supply chain processes to streamline fulfillment and enhance customer experiences (Deloitte 2023).

Starship Technologies and Nuro: Smaller autonomous ground vehicles have also gained traction. Starship Technologies deploys sidewalk-based robots for last-mile deliveries in neighborhoods and college campuses. These robots autonomously navigate pedestrian spaces, delivering groceries and parcels efficiently. Nuro focuses on autonomous delivery vehicles for groceries and meals in suburban areas, employing advanced AI to operate safely amidst traffic and pedestrians. By mitigating labor constraints, these vehicles scale cost-effectively during peak demand periods (KPMG 2023).

AI-based route optimization algorithms are key to maximizing the potential of autonomous logistics. These algorithms analyze extensive datasets—spanning traffic conditions, weather patterns, road closures, and real-time order flows—to determine the safest, most efficient delivery paths (Gomes et al. 2022). In congested urban zones, the system may reroute an autonomous van or drone mid-journey if it detects new congestion or hazards. Similarly, in rural or hard-to-reach regions, AI tools can direct drones to adopt alternate flight paths in response to local weather changes or terrain challenges. Such dynamic adaptation not only cuts travel time and fuel usage but also maintains consistent delivery service levels (Deloitte 2023).

Hybrid models, where drones and autonomous ground vehicles collaborate, have further expanded last-mile capabilities. In this approach, a ground vehicle transports goods to a designated “mobile hub” location. Drones then assume the final delivery leg, traversing short distances to customer addresses that may lack direct road access. This synergy balances the strengths of both platforms—ground vehicles handle bulk transport efficiently, while drones excel in nimble, point-to-point drops (KPMG 2023).

In emerging economies where infrastructures can be inconsistent, drones and autonomous vehicles offer innovative solutions for bridging logistical gaps (PwC 2025). Drones, in particular, circumvent deteriorated roads or challenging terrains, expediting deliveries of essentials like medicine, food, or hygiene products in remote villages (Deloitte 2023). The rapid deployment of drone services in Africa’s healthcare sector, for instance, demonstrates how these technologies can significantly improve outcomes by ensuring timely delivery of critical supplies. Adopting drones and AGVs can thus foster social impact while simultaneously strengthening local economies and supply chain resilience (Gomes et al. 2022).

Sustainability stands as a major driver for the continued evolution of intelligent logistics. The environmental benefits of autonomous vehicles and drones—like lower fuel consumption and reduced carbon emissions—align with corporate ESG goals and regulatory pressures (Gomes et al. 2022). Some research also explores solar-powered drone fleets or hybrid vehicles, highlighting the potential for truly carbon-neutral logistics systems in the long run (PwC 2025). Concurrently, advances in AI, sensor technology, and battery efficiencies suggest ongoing improvements in reliability and range, paving the way for broader global adoption of autonomous last-mile solutions (KPMG 2023).

Ultimately, the convergence of robotics, AI, and IoT in intelligent logistics signifies a paradigm shift in supply chain management. By bypassing conventional traffic bottlenecks, automating route adjustments in real time, and leveraging hybrid models of transport, companies can meet stringent customer expectations for speed and convenience across varied geographies (Deloitte 2023). As the technology matures, its application in both developed and emerging markets will likely expand, culminating in highly adaptable, cost-effective, and customer-centric logistics networks that redefine last-mile delivery (Gomes et al. 2022).

4.4. Integration of Circular Economy Principles

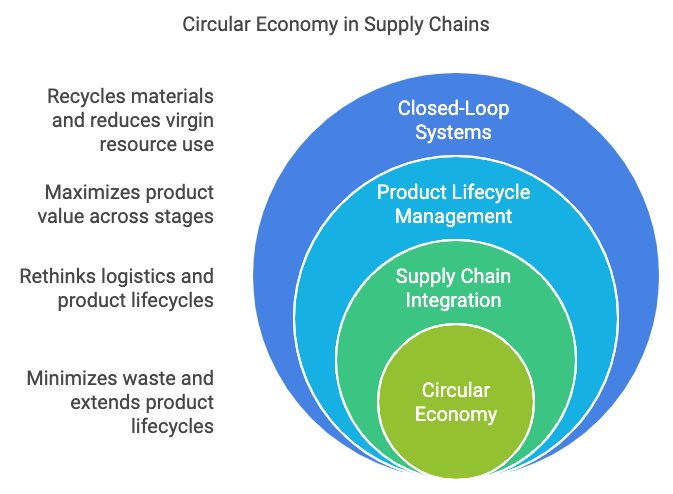

The circular economy offers a transformative framework for resource management, emphasizing the reuse, remanufacturing, and recycling of products and materials to minimize waste and extend product lifecycles (Zhang et al. 2021). Unlike traditional linear supply chains rooted in extraction and disposal, circular models continuously circulate resources through closed-loop systems, thus reducing dependence on virgin inputs and lowering environmental impacts (KPMG 2023). According to a 2022 PwC report, nearly 60% of large multinational firms have started piloting circular economy initiatives, reflecting heightened awareness of sustainability imperatives, regulatory pressures, and shifting consumer expectations (PwC 2022).

Figure 4: Transformative Approach to Resource Management

One foundational element in integrating circular economy principles into supply chains is Product Lifecycle Management (PLM). By designing goods for durability, ease of repair, and recyclability, PLM extends product lifespans and aligns manufacturing processes with sustainable objectives (Bianconi and Xu 2022). This approach necessitates robust reverse logistics systems, which handle the flow of returned items for refurbishment, remanufacturing, or recycling. In practice, reverse logistics channels reintroduce recovered materials into production, reducing the need for virgin resources and shrinking ecological footprints (EY 2025). For companies in emerging markets, where infrastructure may be less developed, circular strategies foster local recycling initiatives and create new economic opportunities—such as material recovery services—promoting both resource conservation and entrepreneurial growth (Deloitte 2024).

IKEA provides a prominent example of circular implementation at scale. Through the “Circular Hub,” IKEA resells gently used or returned items at discounted prices, extending product life while reducing waste (Deloitte 2024). Simultaneously, the company incorporates recycled and renewable materials into product lines, aligning with its ambition to become a fully circular enterprise by 2030. Such efforts underscore how closed-loop systems can drive brand loyalty and generate cost savings via reduced resource consumption (Zhang et al. 2021).

Patagonia similarly embeds circularity through its “Worn Wear” program, allowing customers to trade in used garments for store credit. The company repairs and resells these items, minimizing textile waste and reinforcing a sustainability-focused brand image (KPMG 2023). Patagonia’s approach extends beyond reuse; it also invests in recycled materials—like polyester sourced from discarded plastic bottles—helping the firm reduce reliance on virgin inputs and lessen its carbon footprint (Bianconi and Xu 2022).

Sectors with high product complexity, such as electronics and automotive, increasingly adopt circular practices through stringent reverse logistics processes (PwC 2022). Regulatory frameworks around electronic waste drive companies to develop take-back programs, refurbishing or recycling devices. In automotive, components like batteries and engines undergo remanufacturing or material recovery, lowering lifecycle emissions and contributing to compliance with environmental regulations (Zhang et al. 2021). By enabling companies to reclaim valuable materials, reverse logistics not only mitigates ecological impact but also uncovers new revenue streams through refurbished product lines and secondary part markets (EY 2025).

Technological innovations in AI and IoT have accelerated circular adoption by providing detailed insights into product conditions, usage patterns, and maintenance requirements (Bianconi and Xu 2022). AI-driven analytics can forecast when components are likely to fail, facilitating proactive repairs that prolong product life. IoT sensors track real-time data on location and operational status, streamlining reverse logistics by determining whether items qualify for refurbishment, remanufacturing, or recycling (KPMG 2023). In manufacturing settings, such systems optimize maintenance schedules, minimize unplanned downtime, and reduce waste by ensuring timely part replacements (Deloitte 2024).

Additionally, circular supply chain platforms are emerging as collaborative ecosystems where businesses share resources, repurpose industrial byproducts, and co-develop waste-reduction initiatives (Zhang et al. 2021). Such platforms enable more efficient cross-company material flows and foster the development of local recycling and remanufacturing clusters. They are especially beneficial in regions with underdeveloped waste management infrastructures, where shared logistics networks can amplify the impact of circular principles (EY 2025).

Integrating circular economy principles can yield multifaceted advantages, ranging from regulatory compliance and cost savings to innovation in product design and consumer engagement. Circular supply chains decrease vulnerability to resource scarcity, alleviate environmental pressures, and enhance brand reputation among eco-conscious consumers (PwC 2022). For emerging markets, circular models not only conserve natural capital but also catalyze new business opportunities in repair services and material recovery operations (Deloitte 2024). As global interest in sustainability intensifies, the convergence of AI, IoT, and collaborative platforms is poised to deepen circular adoption, creating more resilient and ecologically responsible supply chain networks (KPMG 2023).

4.5. Resilient Supply Chains

Supply chain resilience refers to the ability of a supply chain to anticipate, withstand, and recover from disruptive events, ensuring a continuous flow of goods and services despite uncertainties (Lee et al. 2021). In an era characterized by frequent natural disasters, geopolitical tensions, and evolving consumer demands, resilience has become a strategic imperative for companies worldwide (KPMG 2023). Integrating artificial intelligence (AI) into supply chain risk management offers advanced capabilities for predicting and mitigating risks, enabling organizations to maintain operational stability even under adverse conditions (Deloitte 2024). By processing large-scale real-time data and simulating multiple disruption scenarios, AI empowers supply chain managers to adopt proactive and data-driven approaches to risk preparedness and crisis response (PwC 2025).

Traditional supply chain risk management often relied on historical data and manual contingency planning, rendering it largely reactive in the face of unforeseen crises (Bai et al. 2022). In contrast, AI-based systems continuously monitor diverse data feeds—ranging from weather forecasts and macroeconomic indicators to social media chatter—detecting early warning signals that could indicate emerging disruptions. Machine learning models analyze patterns in these datasets to generate predictive insights, alerting decision-makers to potential risks before they fully materialize (KPMG 2023). For instance, if a typhoon is projected to hit a region hosting a critical supplier, an AI tool can quantify the likely impact on production and logistics, prompting supply chain managers to secure alternative sources or expedite shipments preemptively.

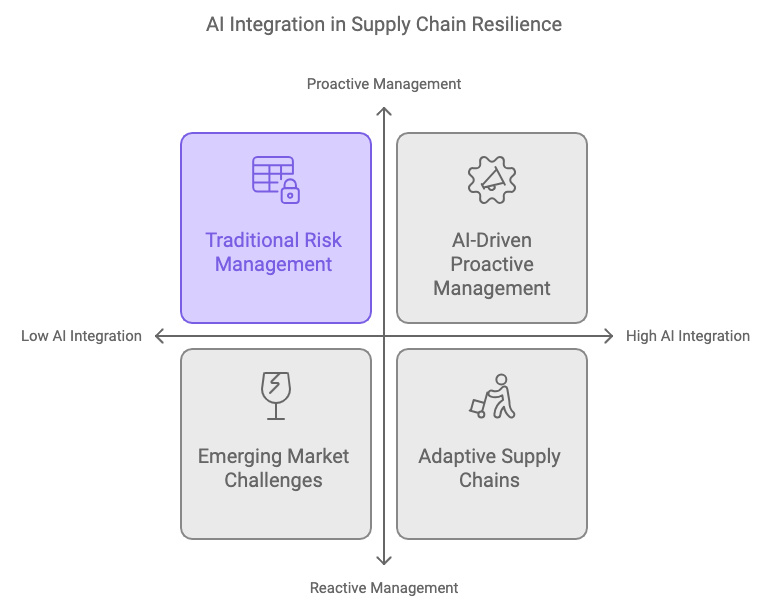

Figure 5: AI-driven proactive management offers high integration and proactive management.

DHL has adopted AI-powered platforms for real-time risk assessment, integrating data on traffic flows, weather conditions, and economic trends (Lee et al. 2021). By analyzing these variables continuously, DHL’s system predicts disruptions in logistics networks, suggesting rerouting options and alternative transportation modes. This agility proved invaluable during recent global events—such as pandemic-related restrictions—where quick pivots were critical to maintaining timely deliveries (Deloitte 2024).

Maersk employs AI to map vulnerabilities across its extensive shipping ecosystem. AI-driven analytics highlight potential single points of failure—like congested ports or critical supplier dependencies—allowing Maersk to build redundancy through route diversification and modular logistics strategies (Bai et al. 2022). When unforeseen disruptions occur, Maersk’s system reroutes cargo automatically, reducing delays and minimizing revenue losses. This proactive approach supports not only Maersk’s own operations but also the broader global supply chains reliant on its shipping services (KPMG 2023).

One transformative application of AI in resilience is supply chain mapping, providing a bird’s-eye view of global supplier networks. By visualizing every node—from raw material providers to distribution centers—companies identify critical dependencies and single points of failure (PwC 2025). AI-enhanced mapping tools continuously update these visualizations, highlighting changes in supplier capacity or regional risk factors. This dynamic perspective is essential for crafting targeted contingency plans and ensuring that no overlooked bottleneck jeopardizes operations (Lee et al. 2021).

Digital twins—virtual replicas of physical supply chain assets—take this mapping concept a step further, enabling real-time simulation of potential disruptions. By mirroring warehouses, transport routes, and production lines, digital twins allow companies to test alternate sourcing strategies, reroute shipments, or adjust production schedules without interrupting actual operations (Deloitte 2024). For instance, an automotive manufacturer can simulate the impact of a port shutdown on its assembly lines, then evaluate different shipping routes or supplier shifts to minimize production halts. This predictive capability significantly improves emergency readiness and enhances decision-making in the face of uncertainty (Bai et al. 2022).

In emerging economies, infrastructural vulnerabilities and regulatory uncertainties can amplify supply chain disruptions. AI-based resilience tools help companies in these regions anticipate weather-related challenges, political unrest, or fluctuating currency rates (KPMG 2023). By integrating digital twins and predictive analytics, firms can evaluate various operational scenarios—such as alternative shipping corridors or emergency stockpiling strategies—and adapt swiftly when disruptions strike. This proactive risk management fosters smoother logistics operations, bolstering competitiveness and economic growth in markets that historically have been more exposed to supply chain shocks (Lee et al. 2021).

AI-driven resilience not only safeguards individual organizations but also stabilizes interconnected supply networks across the globe. When multiple stakeholders implement predictive models and real-time risk monitoring, the ripple effects of disruptions are minimized, fostering greater reliability for consumers and trading partners (PwC 2025). Moreover, evolving AI technologies—such as reinforcement learning and advanced optimization algorithms—promise further refinements in scenario simulation and resource allocation (Deloitte 2024). As climate-related disasters and geopolitical frictions persist, the significance of adaptive, AI-enabled supply chain resilience will continue to grow, solidifying its role as a fundamental pillar of modern business strategy (Bai et al. 2022).

4.6. Conclusion and Further Learning

In conclusion, innovations in supply chain operations, driven by AI, autonomous technologies, and sustainability practices, are revolutionizing how businesses manage logistics, procurement, and risk. By adopting smart warehousing, intelligent logistics, and circular economy principles, companies can achieve higher operational efficiency, reduce environmental impact, and build resilient supply chains that are prepared to withstand disruptions. These advancements represent the future of supply chain management, offering a blueprint for businesses to remain competitive and sustainable in the digital age.

Delving into these prompts offers a unique opportunity to deepen your understanding of the innovations shaping the future of supply chain operations. Each question is designed to push the boundaries of your knowledge, encouraging you to explore how cutting-edge technologies like AI, autonomous systems, and sustainability practices can revolutionize logistics, procurement, and risk management.

How do autonomous robots, equipped with advanced AI and machine learning algorithms, improve operational efficiency in smart warehouses by automating tasks such as picking, sorting, and inventory management, and what are the key challenges—such as infrastructure, workforce adaptation, and cybersecurity—when scaling their deployment across global supply chains?

What are the core features of AI-driven inventory management systems, such as real-time data processing, predictive analytics, and machine learning models, and how do these systems optimize stock levels, minimize waste, and ensure demand responsiveness across multiple geographies in the supply chain?

How do collaborative robots (cobots), designed to work alongside human operators, enhance productivity, safety, and flexibility in warehouse environments, and what advanced safety protocols and human-robot interaction (HRI) techniques must be in place to ensure seamless and secure collaboration?

What specific roles does AI play in transforming smart procurement processes, particularly in assessing supplier risks, forecasting market trends, and negotiating contracts, and how does AI-driven predictive modeling help companies optimize cost efficiency and supplier reliability in volatile markets?

How can AI-driven procurement systems help companies navigate the complexities of global sourcing, including challenges such as geopolitical risks, fluctuating raw material prices, and changing trade regulations, and what key algorithms and data analysis techniques can be employed to ensure strategic decision-making?

What are the key technologies—such as AI, IoT, GPS, and edge computing—enabling the use of drones and autonomous vehicles for last-mile delivery, and how do these technologies impact cost efficiency, delivery speed, fuel consumption, and the overall customer experience in logistics operations?

How do AI algorithms optimize delivery routes for autonomous vehicles, taking into account real-time factors such as traffic, weather conditions, fuel efficiency, and delivery windows, and how do these algorithms dynamically adjust routes to enhance efficiency and reduce operational costs in last-mile delivery?

How can drones and autonomous vehicles be effectively integrated into existing logistics networks, particularly in complex urban environments with regulatory constraints, and what technological, legal, and operational considerations need to be addressed to ensure seamless adoption at scale?

What are the fundamental principles of the circular economy, such as resource recovery, product life extension, and waste minimization, and how can supply chains integrate these principles by rethinking product design, reverse logistics, and material flow to enhance sustainability and reduce environmental impact?

How does AI support the implementation of circular economy practices in supply chain management by tracking product life cycles, identifying reuse and recycling opportunities, and optimizing reverse logistics, and what role does data analytics play in creating more sustainable, closed-loop systems?

What are the key challenges—such as infrastructure, cost, and customer acceptance—of integrating reverse logistics into traditional supply chain models to support product reuse, remanufacturing, and recycling, and what are the best practices for overcoming these barriers and achieving sustainable supply chain management?

How can AI and predictive analytics improve risk management in supply chains, particularly in forecasting disruptions caused by geopolitical events, natural disasters, or supplier failures, and how do AI-driven models assess the probability and impact of these risks to create more resilient supply chain strategies?

What role do digital twins—virtual replicas of physical assets and processes—play in enhancing supply chain resilience, and how can companies use digital twins to simulate potential risks, test mitigation strategies, and optimize decision-making in real-time to protect against disruptions?

How can companies implement AI-driven contingency planning to proactively protect their supply chains from disruptions, and what are the key components—such as scenario planning, predictive modeling, and real-time monitoring—of an effective AI-based risk management strategy?

What are the key innovations in AI for supply chain risk mitigation, such as real-time data processing, advanced forecasting models, and machine learning algorithms, and how do these innovations enable companies to improve decision-making, anticipate disruptions, and maintain supply chain continuity during crises?

How can companies balance the high upfront costs of implementing autonomous technologies, such as robots and drones, with the long-term benefits—such as increased efficiency, reduced labor costs, and enhanced scalability—offered by these innovations in supply chain operations, and what financial metrics should be considered to evaluate their ROI?

How does AI enable real-time decision-making in smart warehousing and logistics, and what critical technologies—such as IoT, edge computing, and machine learning—are driving the shift toward autonomous, data-driven operations that optimize supply chain performance?

What role does blockchain technology play in enhancing transparency, security, and traceability within circular supply chains, particularly for tracking recycled and refurbished products, and how does it contribute to building consumer trust and ensuring compliance with sustainability regulations?

How can companies assess the ROI of adopting drones and autonomous vehicles for last-mile delivery, and what key factors—such as operational costs, environmental impact, customer satisfaction, and scalability—should be considered in evaluating the long-term benefits of these technologies?

What are the emerging trends in AI, automation, and autonomous technologies for enhancing supply chain resilience, and how will these trends shape the future of global supply chains by enabling companies to proactively mitigate risks, streamline operations, and adapt to evolving market conditions?

By engaging with these topics, you’ll gain valuable insights into the practical applications of these innovations and how they can drive efficiency, resilience, and sustainability in real-world supply chains. Embrace this journey of discovery, and let these prompts inspire you to become a leader in the smart supply chain revolution.

Comments