Chapter 1

Introduction - The Evolution of Supply Chains in the Digital Age

"The supply chain is no longer a back-office operation but a front-office driver of growth, innovation, and competitive differentiation." — Tom Linton, former Chief Supply Chain Officer at Flex.

This chapter introduces readers to the transformation of supply chains in the digital era, focusing on how advanced technologies like AI, IoT, and blockchain are revolutionizing traditional logistics. It explores the shift from linear supply chains to dynamic, interconnected networks, highlighting the business drivers behind this change, such as the need for efficiency, agility, and customer-centric solutions. The chapter also delves into the challenges faced by modern supply chains, including cybersecurity risks and operational complexities, while outlining the opportunities for growth and sustainability brought about by digital innovations.

1.1. Defining the Smart Supply Chain: Key Characteristics

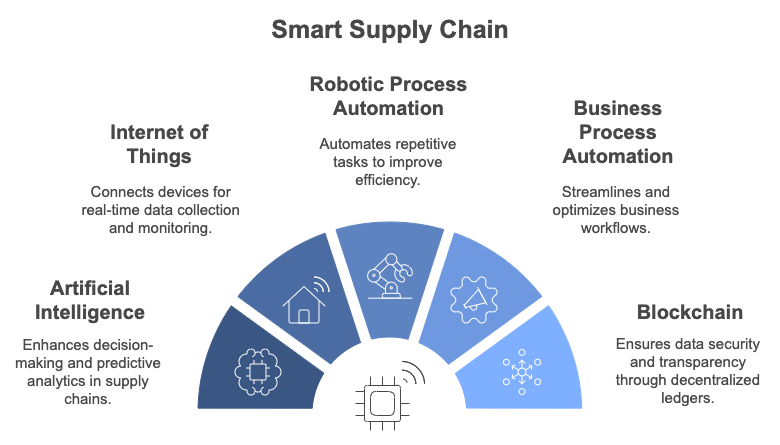

A Smart Supply Chain represents a profound transformation in supply chain management, characterized by the integration of advanced digital technologies that significantly enhance efficiency, agility, sustainability, and transparency. Over the past few years, academic studies and industry reports have underscored how these digital innovations not only optimize operational performance but also bolster resilience, a quality especially critical in a world still recalibrating from pandemic-related disruptions (KPMG 2023). At the foundation of a Smart Supply Chain are technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), Robotic Process Automation (RPA), Business Process Automation (BPA), Blockchain, and Digital Twin. These technologies work in synergy to enable streamlined operations, agile responses to both demand fluctuations and external shocks, and a level of transparency that fosters trust, compliance, and sustainability across the supply chain (PwC 2024).

Figure 1: Key Characteristics of Smart Supply Chain

Real-time data and automation serve as the core drivers of smart supply chain functionality (Li et al. 2022). IoT sensors embedded across the supply chain continuously capture data on location, condition, and movement of goods, enabling the kind of real-time visibility that is crucial for responsive logistics and risk mitigation. This data is then processed through AI algorithms, which provide predictive analytics, helping companies anticipate demand fluctuations, optimize inventory levels, and minimize disruptions (Smith et al. 2023). Automation through RPA and BPA reduces the burden of routine tasks, enabling human resources to focus on higher-level decision-making and strategic planning. Meanwhile, Blockchain technology offers a secure, immutable ledger of all supply chain transactions, providing transparency and traceability, particularly valuable in sectors with stringent regulatory requirements and sustainability targets, such as pharmaceuticals, food, and consumer goods (EY 2021).

Digital Twin technology elevates this integration further by creating virtual replicas of physical supply chain assets and processes. These digital representations enable organizations to simulate a variety of scenarios and test potential strategies in a controlled environment before implementing them in real-world operations (Miller et al. 2021). For instance, a manufacturer can use a digital twin to simulate the impact of a production delay on downstream operations, proactively identifying and mitigating risks. By offering actionable, data-driven insights, digital twins support prescriptive decision-making, allowing supply chains to rapidly adapt to changes. This capability is increasingly important in both global and emerging markets, where uncertainties—such as volatile demand, infrastructure constraints, or policy shifts—can significantly impact supply chain performance (Deloitte 2022, KPMG 2023).

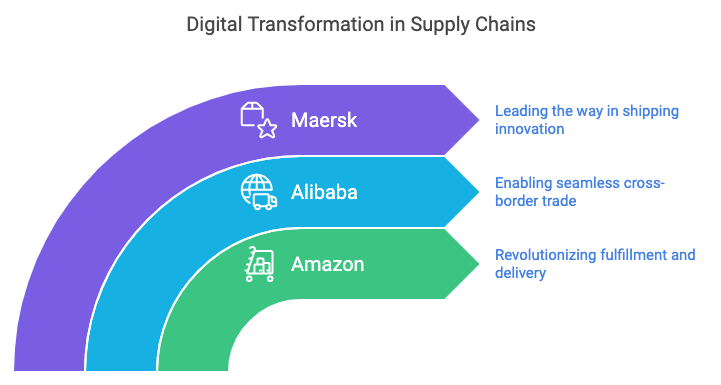

The implementation of Smart Supply Chain practices is visible across global leaders that have embraced comprehensive digital transformations, setting benchmarks for efficiency, speed, and transparency. Amazon, for instance, has revolutionized fulfillment and delivery by using AI, IoT, robotics, and automation in synergy. In the company’s fulfillment centers, robotic systems handle tasks like picking, packing, and sorting, while AI-powered algorithms accurately forecast demand, optimizing inventory and minimizing stockouts. Combined with IoT-enabled asset tracking, Amazon can operate at a scale that meets global customer expectations, rapidly adapting to demand shifts and strengthening its resilience to disruptions.

Similarly, Alibaba’s logistics arm, Cainiao, has developed a Smart Supply Chain that integrates Blockchain and IoT technologies to enable seamless cross-border trade, particularly in Southeast Asia’s diverse regulatory landscape (Chen et al. 2022). Blockchain ensures the authenticity of goods, providing verifiable proof of origin—a critical advantage in complying with international regulations. Meanwhile, IoT systems monitor packages in real time, enabling proactive disruption management and building trust among stakeholders. This level of visibility has proven vital for Alibaba in overcoming logistical challenges that arise from operating across vastly different infrastructure and regulatory environments.

Maersk, one of the world’s largest shipping and logistics companies, has similarly embraced Blockchain, IoT, and digital twin technologies in its TradeLens platform. Through Blockchain, Maersk provides transparency in cargo tracking and facilitates secure data sharing among supply chain stakeholders, significantly reducing fraud and documentation bottlenecks (Maersk 2021). IoT-enabled containers relay real-time location and condition data, ensuring safe shipments and timely delivery. Digital twin technology augments these advantages by simulating complex logistics scenarios, optimizing route planning, and improving the accuracy of delivery forecasts (Miller et al. 2021). Collectively, these approaches highlight how digital solutions can enhance operational efficiency while promoting transparency and security.

Figure 2: Case Study - Digital Transformation

Emerging markets are also increasingly adopting smart supply chain technologies to address unique regional challenges and achieve significant leaps in efficiency and customer satisfaction. In India, Flipkart has employed AI and machine learning algorithms to streamline last-mile delivery in densely populated areas, using real-time traffic and delivery data to dynamically route vehicles for faster service. In Brazil, logistics providers like iFood have integrated IoT-enabled cold chain systems to ensure perishable goods maintain freshness under tropical conditions. By tracking temperature and humidity in real time, these systems ensure food safety, reduce waste, and build consumer trust—crucial in a market increasingly concerned with product quality and sustainability.

The advent of new digital tools and analytical methods has ushered in a new era of precision, automation, and responsiveness in supply chain management.

AI-Powered Forecasting and Optimization: AI-driven systems analyze massive datasets—ranging from historical transactions to market trends—allowing companies to predict demand with high accuracy and plan routes more effectively. Such foresight helps businesses maintain optimal inventory levels, reducing both stockouts and surplus.

IoT-Enabled Asset Tracking: IoT sensors attached to products or transport vehicles monitor environmental factors like location, temperature, and humidity, making real-time visibility and control possible. In industries like pharmaceuticals and food, continuous data feeds help maintain product integrity, reduce waste, and comply with stringent regulatory standards. Automated inventory management further ensures that organizations can reconcile physical and digital stock levels, mitigating errors and enhancing overall supply chain responsiveness.

Digital Twin Simulations: Digital twins integrate IoT data and historical records into high-fidelity simulations, enabling predictive and prescriptive analytics. Managers can test scenarios—like a sudden spike in demand or an unexpected delay in production—within the digital environment, proactively adjusting routes, production schedules, or sourcing strategies. This capability is especially valuable in regions prone to infrastructure vulnerabilities or regulatory fluctuations, as it allows for more effective contingency planning.

As the digital era continues to evolve, the Smart Supply Chain is fast becoming a cornerstone strategy for companies worldwide. The integration of AI, IoT, RPA, BPA, Blockchain, and Digital Twin technologies offers a multi-faceted approach to meeting today’s complex market demands, encompassing everything from just-in-time delivery to sustainability goals. In both advanced and emerging economies, these technologies promise a supply chain that is more efficient, adaptive, and resilient—equipping organizations with the capability to leverage real-time data, automation, and predictive analytics for competitive advantage. By embracing these technologies, companies are not only optimizing cost and service levels but also laying the groundwork for long-term resilience and sustainable growth in an increasingly interconnected global marketplace.

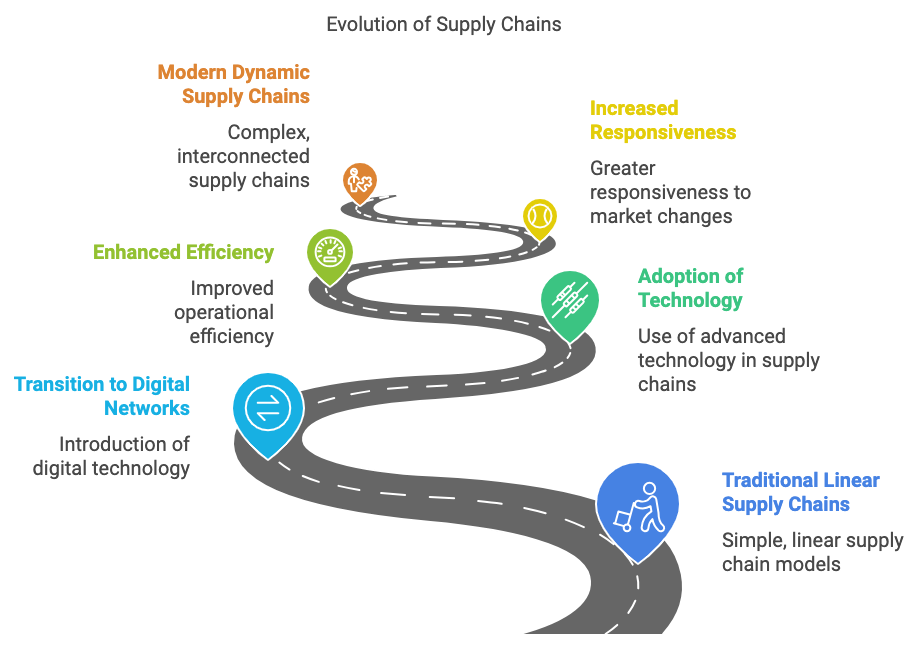

1.2. Historical Evolution: From Linear to Dynamic Networks

Supply chain management has undergone a profound transformation, evolving from simple, linear models into intricate, highly networked systems (Zhang et al. 2023, Deloitte 2023). In the traditional linear paradigm, goods moved sequentially from suppliers to manufacturers to distributors, with minimal integration among the various stages. This arrangement often led to siloed operations and limited visibility, rendering supply chains susceptible to volatile market conditions and external shocks. For much of the 20th century, companies adopted a “push” model that relied on forecasts, resulting in inefficiencies such as large inventory buffers and long lead times (Johnson et al. 2021). As globalization intensified and consumer demands grew more sophisticated, the constraints of this linear system became increasingly apparent.

Figure 3: Historical Evolution of Supply Chains

A major shift toward more agile and responsive supply chains began with the adoption of data-driven processes and real-time information sharing. Instead of relying solely on manual or paper-based records, organizations started implementing enterprise resource planning (ERP) systems, barcoding, and eventually radio-frequency identification (RFID) technologies to track inventory. These innovations paved the way for a “pull” model, where actual demand rather than anticipated sales guided production and distribution. This evolution not only minimized waste but also helped companies become more responsive to market fluctuations and consumer preferences. The automotive industry offers a classic example: Japanese manufacturers, most notably Toyota, introduced just-in-time (JIT) practices in the 1970s and 1980s, transforming how automotive supply chains managed supplier relationships, production line scheduling, and inventory control. The success of JIT catalyzed a broader shift toward lean principles across multiple sectors, from electronics to consumer goods.

By the late 20th and early 21st centuries, advanced IT systems and the emergence of the Internet further reshaped supply chains, leading to the interconnected networks we see today. In the electronics sector, Dell pioneered build-to-order and direct-to-consumer strategies that drastically reduced inventory while enhancing customization and delivery speed. Dell’s agile approach exemplified how shifting from a linear to a dynamic model could bolster competitiveness, particularly in industries where technology evolves rapidly and product life cycles are short. Other leading organizations, recognizing the need for speed and customer responsiveness, similarly embraced real-time analytics and digital platforms to gain end-to-end visibility and foster tighter collaboration with suppliers and distributors.

Modern supply chains now rely on a range of innovations that enable real-time data exchange and near-instant decision-making. Multi-modal logistics is one such breakthrough, integrating air, sea, rail, and road freight in a cohesive manner. According to a Deloitte (2023) study, companies adopting multi-modal approaches can reduce total transportation costs by up to 15% in emerging markets, where inconsistent infrastructure and regulatory environments pose significant challenges. The automotive sector has been among the first to leverage these solutions, using integrated transport networks to mitigate risks related to component shortages or production bottlenecks.

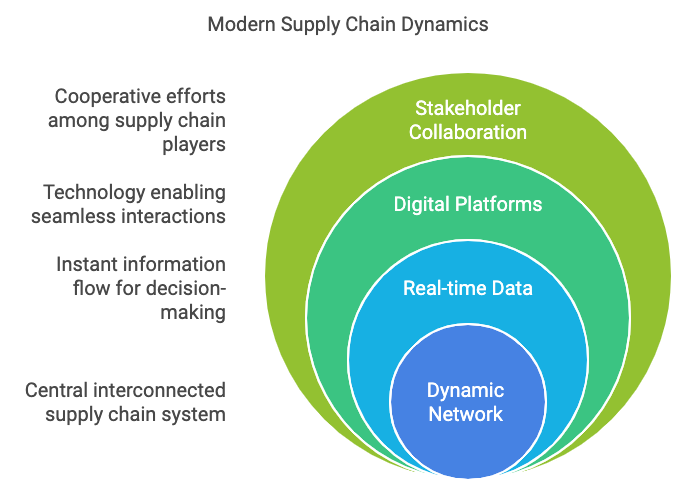

Figure 4: Key Components of Modern Supply Chain

The rise of smart warehouses has further bolstered the shift toward dynamic, connected supply chains. Unlike traditional distribution centers that relied heavily on manual labor, smart warehouses employ robotic picking systems, automated guided vehicles (AGVs), and AI-driven inventory management tools. Amazon’s fulfillment centers, for example, heavily utilize robotics and machine learning algorithms to expedite order processing, thereby meeting consumer expectations for swift deliveries. This high level of automation is sustained by interconnected supply chain platforms that track global inventory and shipments, reducing the likelihood of delays and improving overall service quality.

Another major development has been the advent of 5G and other high-speed communication technologies that enable real-time data sharing at scale. Low-latency networks have become crucial for the effective deployment of IoT devices and autonomous systems in transportation and warehousing. This connectivity empowers companies to respond to disruptions—such as traffic congestion or equipment failure—immediately, reducing costly downtimes and lost sales opportunities. In emerging markets, where infrastructure often lags behind demand, 5G connectivity presents a leapfrog opportunity by offsetting the limitations of underdeveloped physical networks.

The transformation from linear structures to dynamic networks has yielded substantial benefits in both developed and emerging economies. Real-time supply chain visibility and data analytics allow organizations to optimize routes, cut energy consumption, and reduce lead times, while multi-tier collaboration helps stakeholders adapt to sudden changes in demand or regulatory conditions. In markets like India and Brazil, such digital networks are helping local businesses overcome infrastructural constraints, drive sustainability efforts, and meet the rising expectations of a growing middle-class consumer base.

Looking forward, these evolving networks are poised to become even more interconnected and proactive, powered by artificial intelligence, blockchain, and digital twin technologies that allow for advanced scenario planning, predictive maintenance, and robust traceability. As these technologies mature, supply chain practitioners will likely witness an acceleration in the shift from reactive models to truly intelligent, self-orchestrating networks capable of seamless adaptation to market volatility. The historical trajectory—from push-based production lines to responsive, digitally enabled ecosystems—demonstrates that continuous innovation is not just beneficial but essential for thriving in a global marketplace. It is within this context that modern supply chains, both in developed and emerging regions, continue their evolution, redefining operational excellence and strategic competitiveness in the digital age.

1.3. Business Drivers for Digital Supply Chains

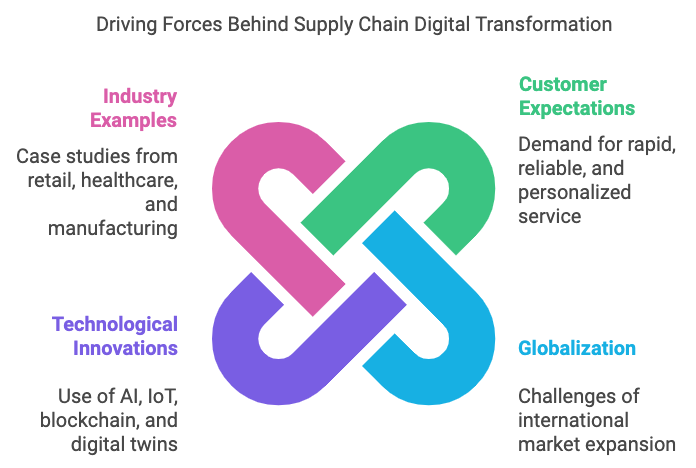

The digital transformation of supply chains is propelled by a series of powerful business imperatives—ranging from heightened customer expectations and globalization to sustainability goals and cost pressures (Chang et al. 2023, Deloitte 2023). As consumer demands continue to evolve, the need for faster delivery, real-time order tracking, and highly personalized service has intensified. In retail and e-commerce, for instance, same-day or even two-hour delivery has become commonplace in many markets, raising the bar for logistical speed and accuracy. Meeting these escalated expectations requires companies to integrate technologies—such as IoT sensors, AI-driven analytics, and automated fulfillment systems—to streamline operations, reduce errors, and provide full visibility throughout the supply chain (Chen et al. 2022, KPMG 2024).

Figure 5: Key Business Drivers for Digital Transformation

Moreover, globalization has significantly expanded both the opportunities and the challenges for modern supply chains. Organizations entering new markets face a variety of risks, including diverse regulatory standards, complex logistical frameworks, and competition from local and multinational players. In such volatile environments, agility becomes critical. Digital supply chains leverage technologies like AI, Blockchain, and IoT to create adaptive networks capable of absorbing disruptions and responding swiftly. Predictive analytics can identify emerging demand patterns or production bottlenecks, while real-time IoT data improves shipment visibility and transparency, enabling organizations to adjust routes and schedules on the fly.

One of the most transformative tools driving supply chain digitalization is Digital Twin technology, which generates virtual replicas of physical supply chain assets and processes. These digital counterparts serve as low-risk environments for experimentation, allowing managers to simulate various “what-if” scenarios and optimize decision-making. For example, a manufacturer anticipating a sudden surge in demand—due to seasonal factors or unexpected market trends—can use a digital twin to model the impact on production lines, shipping routes, and inventory buffers. By testing different contingency strategies, the organization can pinpoint cost-effective and timely responses before implementing them in real-world operations. Digital twins thus empower companies to pivot quickly and confidently in increasingly unpredictable markets (Chen et al. 2022).

Digital transformation has reshaped supply chains across multiple sectors, enhancing efficiency, sustainability, and resilience:

Retail: Walmart’s End-to-End Visibility. Retail giants like Walmart have adopted IoT sensors, automated warehouses, and AI-based analytics to manage massive global supply networks. IoT-enabled real-time tracking systems and predictive analytics help Walmart maintain optimal inventory levels across thousands of store and fulfillment locations. This approach not only reduces operational costs but also supports sustainability initiatives by minimizing waste and optimizing shipping routes.

Healthcare: Pfizer’s Secure and Compliant Supply Network. In the healthcare domain, companies like Pfizer rely on digital technologies to manage complex pharmaceutical supply chains with strict regulatory mandates. By integrating IoT sensors for temperature control with Blockchain-based ledgers, Pfizer can ensure the integrity of sensitive products (e.g., vaccines) and maintain detailed, tamper-proof records. This level of transparency and traceability became particularly vital during COVID-19 vaccine distribution, highlighting how digital transformation strengthens resilience and compliance.

Manufacturing: Toyota’s Lean-Plus-Digital Approach. Toyota, already renowned for its lean manufacturing principles, continues to set new benchmarks by incorporating AI, robotic process automation, and real-time analytics into its operations. The company’s just-in-time model is augmented by digital twins that simulate potential bottlenecks or line adjustments, enabling Toyota to preserve product quality while reducing waste. This agile production system allows rapid adaptation to shifting market demands and underpins Toyota’s reputation for reliability and efficiency.

Digital transformation is not limited to developed economies. In countries like Brazil and India, where infrastructure gaps and regulatory complexities often pose challenges, digital technologies are proving indispensable. Brazilian agribusinesses, for instance, use IoT sensors combined with satellite technology to monitor crops and optimize logistics, reducing resource usage while maximizing yields. Meanwhile, small and medium-sized enterprises (SMEs) in India are leveraging cloud-based supply chain platforms to coordinate with suppliers, track shipments, and manage inventory in real time—fostering a new level of efficiency and competitiveness.

Several groundbreaking technologies and practices are converging to redefine the supply chain landscape:

Collaborative Digital Platforms: The emergence of digital supply chain platforms enables seamless interaction and data sharing among suppliers, manufacturers, and distributors, consolidating functions like procurement, order fulfillment, and inventory management. Through real-time communication channels, supply chain partners can jointly forecast demand, optimize production schedules, and respond rapidly to unforeseen disruptions.

Blockchain for Transparency and Trust: Blockchain technology ensures secure, tamper-proof records of transactions and product flows, thereby enhancing trust and reducing the risk of fraud. This is particularly valuable in industries—such as pharmaceuticals and food—where compliance and quality assurance are paramount. By providing a single source of verified information accessible to all stakeholders, blockchain reduces administrative overhead and streamlines cross-border operations.

Product Lifecycle Management (PLM) Platforms: PLM platforms integrate design, manufacturing, and logistics data into a unified system, improving cross-functional collaboration and speeding up time-to-market. From concept to end-of-life, PLM ensures that engineering modifications are communicated in real time to supply chain partners, preventing costly errors and ensuring regulatory compliance.

Collectively, these advancements—digital twins, IoT, blockchain, advanced analytics, and collaborative platforms—drive the evolution from linear supply chains toward dynamic, data-driven networks (Chang et al. 2023). They address the fundamental business imperatives of cost reduction, faster delivery, and superior customer experiences, all while bolstering sustainability and compliance (KPMG 2024). For organizations in both advanced and emerging markets, digital transformation represents a critical investment in long-term competitiveness and resilience. By leveraging cutting-edge tools, companies can proactively navigate regulatory changes, geopolitical uncertainties, and fast-shifting consumer preferences—solidifying their position in an interconnected global marketplace where adaptability, transparency, and efficiency are paramount.

1.4. Key Challenges in the Modern Supply Chain Landscape

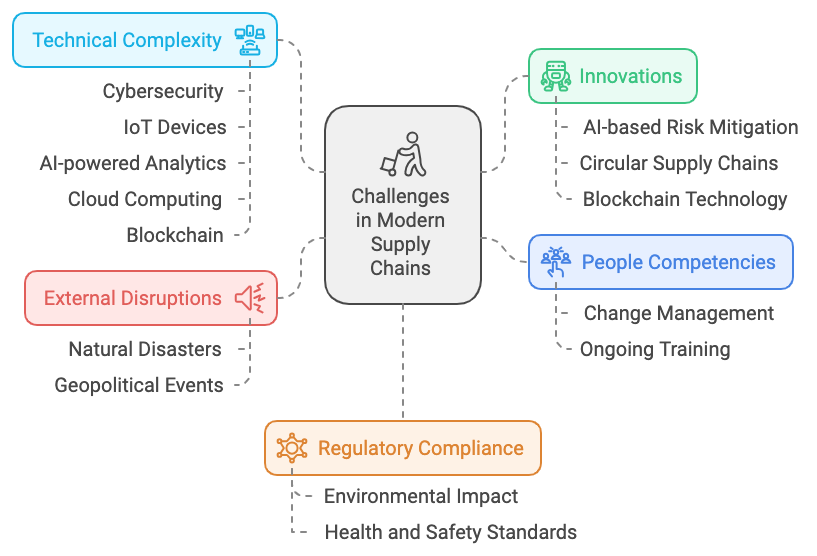

Modern supply chains are increasingly shaped by complexity and volatility, requiring organizations to balance strategic foresight and technological innovation. As digital solutions such as artificial intelligence (AI), the Internet of Things (IoT), and blockchain become integral to operations, supply chains face hurdles related to workforce competencies, cyber risks, regulatory compliance, and environmental sustainability. These challenges have been intensified by disruptions from global events—including the COVID-19 pandemic and geopolitical tensions—prompting companies to seek more resilient, transparent, and adaptive supply chain models.

Figure 6: Challenges in Modern Supply Chains

A major consideration for organizations is ensuring that employees possess the necessary skills to manage emerging digital technologies. Ongoing training and upskilling are essential, particularly as AI-driven analytics and automation displace routine tasks and introduce more data-centric workflows. The emphasis on digital competencies also underscores the importance of effective change management. Industries with longstanding practices—such as automotive manufacturing or pharmaceuticals—often encounter cultural resistance when adopting new technologies. Convincing teams to embrace unfamiliar workflows can be difficult, yet successful adaptation can significantly enhance operational efficiencies and open up new business opportunities.

Modern supply chains also confront technical complexity and persistent cybersecurity threats. Supply chain networks frequently incorporate interconnected devices, cloud platforms, and AI-based systems, creating complex digital ecosystems that must be vigilantly monitored. Cyber attacks can paralyze operations, compromise sensitive data, and damage organizational reputation. The risk of disruptions grows when visibility across multiple tiers of suppliers and logistics providers remains fragmented, often due to legacy systems that were never designed for real-time data sharing. Enhancing security and integrating data streams across diverse IT architectures stand as pivotal steps toward building robust supply chains.

External disruptions such as natural disasters and geopolitical shifts further strain supply chains, underscoring the need for resilience. Events ranging from hurricanes to earthquakes can damage infrastructure and halt production, resulting in cascading delays. Companies operating across multiple countries must also contend with shifting trade policies and tariffs that heighten uncertainty and costs. While these challenges have global implications, they can be especially acute in emerging markets, where infrastructure shortfalls amplify logistical hurdles and constrain the ability to respond quickly to crises.

Regulatory compliance adds another layer of complexity, especially in heavily regulated industries like pharmaceuticals and food and beverage. Companies in these sectors must rigorously track product movements to ensure quality, safety, and adherence to detailed protocols. Labor shortages, often exacerbated by an aging workforce in developed economies, pose additional obstacles to smooth operations. Meanwhile, heightened scrutiny of environmental impact and carbon footprints is compelling organizations worldwide to adopt cleaner, more sustainable practices. These concerns can be magnified in regions experiencing rapid industrialization, where environmental regulations are evolving and natural resources are under increasing pressure.

Traceability has become paramount in industries where product safety and authenticity are critical. For instance, pharmaceutical manufacturers use IoT sensors and blockchain to document each stage of drug production and distribution, ensuring compliance with stringent regulations and offering verifiable proof of product integrity. In the food and beverage sector, blockchain helps reduce fraud and contamination risks by creating an immutable ledger of transactions, an especially valuable feature for managing recalls and regulatory audits. These innovations foster transparency throughout the supply chain, offering competitive advantages by enhancing consumer trust and limiting costly disruptions.

Global disruptions such as the COVID-19 pandemic have amplified the vulnerability of conventional supply chain structures, leading to shortages in essential goods and revealing fundamental weaknesses in sourcing strategies. Lockdowns hindered factory operations and logistics, while demand spikes in protective gear and medical supplies forced companies to reconfigure production lines swiftly. Trade wars and protectionist measures have further pressured organizations to diversify supplier bases and consider nearshoring or reshoring, as reliance on single-source suppliers can be financially and operationally perilous. These pressures have driven the adoption of digital transformation initiatives aimed at bolstering agility and minimizing supply chain risks.

Multiple industries have responded to these challenges with technology-driven strategies. Retailers like Walmart have incorporated AI and IoT to enhance demand forecasting and prevent overstock, reducing waste while ensuring product availability. Pharmaceutical companies such as Pfizer have employed digital tracking solutions to safeguard the distribution of temperature-sensitive products, guaranteeing timely and safe delivery to patients. In manufacturing, Toyota continues to evolve its just-in-time (JIT) practices by integrating advanced analytics, enabling flexible operations that adapt to shifting consumer demands or logistical disruptions.

Recent innovations offer powerful tools for mitigating risks, improving visibility, and fostering sustainability. AI-based risk assessment tools analyze historical and real-time data to predict potential disruptions, from extreme weather events to political instability, allowing companies to proactively realign production schedules or reroute shipments. Circular supply chains are another emerging trend, emphasizing material reuse and recycling to minimize waste and mitigate resource constraints. Sectors such as electronics and fashion are adopting circular practices to manage environmental risks and cater to eco-conscious consumers. Blockchain technology also remains pivotal for building trust and accountability, especially in fragmented global networks where preventing counterfeiting and ensuring consistent quality standards can be challenging.

Collectively, these technologies—AI-based disruption forecasting, circular supply chain models, and blockchain-driven transparency—are transforming how organizations approach both day-to-day operations and long-term strategic planning. As supply chains grow increasingly digital and interconnected, companies in all regions must continually update their approaches to risk management, workforce development, and technology adoption. The future of supply chain management lies in creating networks that can quickly adapt to unforeseen events, comply with evolving regulations, and operate sustainably. Embracing a combination of technological innovations and organizational agility not only safeguards against emerging threats but also positions companies for competitive success in a rapidly changing global environment.

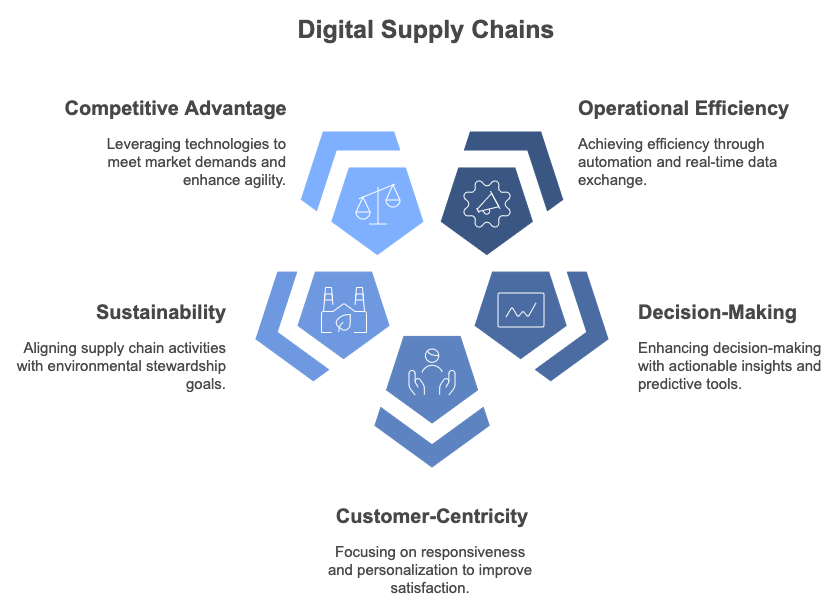

1.5. Opportunities from Digital Supply Chain Revolution

The digitalization of supply chains has ushered in a new era of possibilities that extend beyond operational efficiencies, unlocking data-driven decision-making, customer-centric personalization, and environmental sustainability. Multiple industry reports suggest that automation, powered by AI and machine learning, has helped companies reduce lead times by up to 50% and optimize their resource allocation across the supply chain, thereby enhancing speed and precision in fulfilling market demands. These gains arise largely from real-time data exchange and sophisticated analytics, which minimize human error and streamline once-manual processes.

Another critical opportunity emerging from digitalized supply chains lies in advanced data-driven decision-making. Through AI-enabled analytics, organizations can sift through vast volumes of real-time data, detecting patterns and disruptions in demand and logistics before they escalate into costly problems. This predictive capability empowers companies to pivot rapidly in the face of shifting market conditions, ensuring both resilience and agility. By integrating data from customer interactions and historical sales, supply chains can forecast trends, anticipate demand fluctuations, and tailor offerings to individual consumer preferences—an especially powerful differentiator in markets where customization can drive loyalty.

Figure 7: Key Opportunities of Smart Supply Chains

Sustainability has also emerged as a core focus of the digital supply chain revolution. Many organizations now leverage digital tools to measure and minimize their environmental impact by optimizing transportation routes, reducing excess inventory, and implementing circular practices. By tracking key performance indicators—such as carbon emissions and waste volumes—companies can align their supply chain strategies with environmental stewardship, thus meeting increasingly stringent regulatory standards and satisfying consumer expectations for responsible business operations. This transformation underscores how digital supply chains, beyond delivering cost and efficiency benefits, can serve as conduits for ethical and sustainable value creation.

The competitive advantages enabled by digital supply chains are evident across multiple industries. In e-commerce, for instance, Shopify’s cloud-based platform equips small and medium-sized businesses (SMBs) with end-to-end logistics services, data analytics, and AI-driven demand forecasting. This democratization of supply chain capabilities empowers SMBs to meet international market demands without the extensive infrastructure typically required, effectively leveling the playing field. In the automotive sector, Tesla’s agile supply chain architecture integrates real-time data from connected vehicles, manufacturing operations, and customer feedback to continuously refine production plans and inventory management. Meanwhile, Zara’s fast-fashion model exemplifies how data analytics and IoT-enabled sensors can shorten product development cycles to mere weeks, capitalizing on dynamic consumer trends and minimizing unsold inventory.

Emerging markets have also leveraged digital supply chain technologies to strengthen their standing in global trade. In Vietnam’s textile and garment industry, AI and IoT solutions have accelerated production timelines and bolstered quality control, making local firms more competitive internationally. Kenyan smallholder farmers, similarly, have adopted mobile-based supply chain platforms to gain direct access to real-time market data, thereby improving profitability by bypassing traditional intermediaries. These success stories illustrate how digital transformation can bridge infrastructural gaps, fostering inclusive growth and economic development in regions previously constrained by logistical barriers.

Innovations in AI, machine learning, and digital twin technology form the backbone of these modern supply chains. AI-powered algorithms analyze historical and real-time data to identify disruptions, demand surges, or manufacturing bottlenecks, subsequently recommending adaptive strategies in production and logistics. Machine learning models refine these insights over time, increasing predictive accuracy and operational efficiency. Digital twins build on these capabilities by creating virtual replicas of physical assets and processes, allowing companies to simulate varied scenarios—from a sudden demand spike to a manufacturing line halt—without interrupting actual workflows. This ability to conduct risk-free experimentation has proven invaluable for reducing downtime, lowering costs, and sustaining continuous improvement.

The Internet of Things (IoT) further elevates these capabilities by integrating sensors and smart devices throughout the supply chain. When deviations or breakdowns occur—such as a malfunction in a cold-chain logistics process—IoT-enabled systems can trigger automated responses, alert stakeholders, or self-adjust operating conditions. Such proactive maintenance bolsters supply chain resilience and aligns with corporate sustainability objectives, as it reduces both operational waste and environmental impact. Additionally, blockchain technology serves to enhance security and traceability, particularly in highly regulated industries like pharmaceuticals or food and beverage. By establishing an immutable ledger of transactions, blockchain minimizes fraud and streamlines compliance in cross-border operations, thereby instilling greater transparency and consumer trust.

Beyond these technological advancements, digital supply chains create new avenues for small businesses worldwide to engage in global commerce. Cloud-based logistics and e-marketplaces allow smaller firms to manage cross-border deliveries, optimize inventory holdings, and communicate with international customers—all without substantial upfront capital expenditures. This expansion of market reach has far-reaching implications not only for business growth but also for the economic development of emerging regions, fueling local entrepreneurship and job creation.

In essence, the digital supply chain revolution presents a transformative opportunity for companies in both developed and emerging economies to enhance efficiency, sustainability, and customer satisfaction. By harnessing AI, IoT, blockchain, and digital twin technologies, supply chains evolve into adaptive, data-centric networks capable of responding to market changes with speed and agility. As these innovations continue to advance, the scope for further optimization—encompassing everything from sustainability metrics to cross-border expansion—will only grow, highlighting the imperative for organizations to invest in robust digital ecosystems. Embracing this revolution offers not merely improved operations but also a strategic edge, ensuring resilience and relevance in a competitive global landscape.

1.6. Conclusion and Further Learning

In conclusion, the evolution of supply chains from linear models to dynamic, technology-driven networks is reshaping industries around the globe. To thrive in this new landscape, businesses must embrace digital transformation, leveraging innovations such as AI, blockchain, and IoT to build more resilient, transparent, and efficient supply chains. The ability to adapt to these changes will define a company’s success in an increasingly competitive and volatile market, where sustainability, customer demands, and technological advancements are central to supply chain strategy.

Delving into the following prompts will provide you with valuable insights into the transformative power of digital technologies in supply chains. By exploring each topic, you’ll not only understand the core concepts but also grasp how industry leaders are leveraging innovation to overcome challenges and seize opportunities.

How does the shift from linear supply chains to dynamic, digitally interconnected networks influence logistics efficiency, flexibility, and resilience, particularly in terms of cost optimization, inventory management, and response to disruptions like geopolitical events or natural disasters?

What advanced machine learning techniques and AI-driven algorithms are currently being applied in predictive analytics for supply chain management, and how do they enhance accuracy in demand forecasting, inventory optimization, and real-time decision-making across the supply chain ecosystem?

How does blockchain technology, through its decentralized ledger and smart contract functionalities, ensure end-to-end transparency, enhance trust among stakeholders, and mitigate fraud, especially in complex, multi-tiered global supply chains involving numerous suppliers and partners?

What are the key technological, operational, and organizational characteristics of a smart supply chain, and how do these elements collectively influence business outcomes such as operational efficiency, customer satisfaction, sustainability, and risk management?

How can IoT-enabled asset tracking, through the integration of sensors, GPS, and cloud computing, provide granular, real-time visibility into the location, condition, and movement of goods, and what are the strategic advantages of such visibility in enhancing supply chain performance and agility?

What are the primary business drivers, such as consumer demand, competitive pressure, cost reduction, and regulatory compliance, that compel companies to pursue digital transformation in their supply chains, and how does this transformation create new value propositions in a hyper-competitive market?

How can companies leverage digital twin technology—creating virtual replicas of physical supply chain systems—for real-time simulations, predictive analytics, and scenario planning to optimize logistics operations, enhance inventory management, and reduce operational costs in an increasingly complex global environment?

What are the most critical cybersecurity risks, such as data breaches, ransomware attacks, and supply chain vulnerabilities, that threaten the integrity of modern digital supply chains, and what advanced security strategies, such as zero-trust architectures and blockchain-based solutions, can companies implement to mitigate these risks?

How can AI-driven demand forecasting systems utilize historical data, market trends, and real-time analytics to significantly improve supply chain responsiveness, agility, and accuracy in demand planning, especially in volatile and fast-changing market environments?

What are the operational, environmental, and economic benefits of integrating a circular supply chain model, where materials are reused, recycled, and repurposed, into a business strategy, and how can this model help companies achieve long-term sustainability and competitive advantage?

How do 5G networks and advanced connectivity solutions improve the speed, responsiveness, and real-time decision-making capabilities of global supply chains, particularly in terms of supporting IoT applications, autonomous logistics systems, and end-to-end visibility across complex supply chains?

How can digital platforms, enabled by AI, blockchain, and cloud technologies, streamline supplier collaboration, enhance procurement processes, and create more transparent and efficient supply chains, especially in industries that rely on complex supplier networks and just-in-time manufacturing?

What are the long-term economic benefits of implementing smart supply chain technologies, such as AI, blockchain, and IoT, in terms of cost savings, improved asset utilization, enhanced customer service, and the ability to scale operations efficiently in response to growing market demands?

What strategies and technologies can companies adopt to overcome key challenges in modern supply chains, such as labor shortages, regulatory compliance, and fluctuating demand, while maintaining efficiency, reducing costs, and ensuring seamless operations in the face of ongoing global disruptions?

What are the most effective methods, including the use of renewable energy, electrification of transportation fleets, and digital innovations such as AI-driven route optimization, for reducing carbon emissions in logistics operations, and how can these methods be integrated into a company's overall sustainability strategy?

How has the COVID-19 pandemic reshaped global supply chain strategies, and what long-term changes—such as diversification of suppliers, increased focus on resilience, and the acceleration of digital transformation—are likely to remain permanent in the post-pandemic era?

How does AI enhance decision-making and real-time problem-solving in logistics by analyzing vast amounts of data, identifying patterns, and providing actionable insights to optimize processes such as inventory management, transportation routing, and supplier selection?

How can blockchain technology be applied to improve the traceability of goods and services across global supply chains, ensuring that products are sourced ethically, securely, and sustainably, and how can this transparency drive consumer trust and regulatory compliance?

What are the emerging trends and breakthrough technologies, such as autonomous vehicles, AI-driven supply chain orchestration, quantum computing, and decentralized logistics platforms, that are expected to further shape the future of smart supply chains in the next decade?

How can companies ensure that their digital transformation efforts in supply chains are aligned with sustainability goals, such as reducing carbon emissions and waste, while also improving operational efficiency and meeting stakeholder expectations for responsible business practices?

This learning journey will empower you to think strategically about supply chain transformation, equipping you with the knowledge and skills to drive efficiency, sustainability, and competitiveness in your own organization. Let curiosity guide you as you explore these prompts and unlock the future of supply chain management.

Comments